bauxite ore processing equipment used

bauxite ore processing equipment used

What are the machines used to mine bauxite? LinkedIn

Some common machines used in bauxite mining include: 1Excavators: These are large machines with a rotating bucket that are used to extract bauxite ore from the ground They 2Bulldozers: The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef Bayer Bauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al2O3), the rest being a mixture of silica, various iron oxides, and titanium dioxide The aluminium oxide must be further purified before it can be refined into aluminium metal Bayer process

Mining and Refining Process International Aluminium

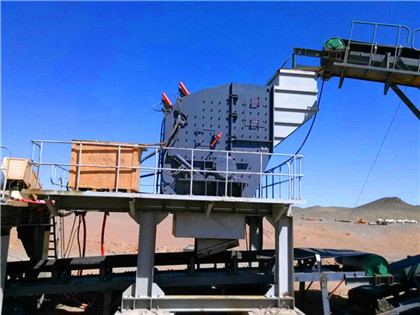

Mining and Refining Process The Bayer Process was invented and patented in 1887 by Austrian scientist Karl Josef Bayer Two to three tonnes of bauxite are required to produce one tonne of alumina 90% of the The equipment selected for the crushing area is chosen based on the physical characteristics of the raw bauxite and the capacity rates required Typical Physical Bauxite Processing: Crushing and Grinding of Bauxite

Modeling of Bauxite Ore Wet Milling for the

Bauxite is a rock type that is used to produce metallurgicalgrade alumina and chemicalgrade alumina/aluminum hydroxide using the Bayer process [ 8 ] During Our solutions for realtime monitoring on conveyor belts (elemental and mineralogical) with its fast feedback loops, enable fast counteractions on changing Bauxite Mining Process Analytical Solutions Malvern

Mineral Processing technologies in the Bauxite and

PDF On Jan 1, 2008, Stephan Buntenbach published Mineral Processing technologies in the Bauxite and Alumina Industry Find, read and cite all the research you need on ResearchGateBulk Mineral Analysis XRD directly measures the mineralogy Knowing about mineral impurities such as clay or iron oxide in bauxite is the key to beneficiation in the alumina refinery and thus reduces residues In the Bauxite Bruker

Bauxite Mining and Alumina Refining PMC National

PROCESS DESCRIPTION: BAUXITE MINING Bauxite is the principal ore of alumina (Al 2 O 3), which is used to produce aluminum (Al) It is composed of Washers: Washers are used to remove impurities from the bauxite ore before it is sent for further processing Refining equipment: Refining equipment, such as mills and kilns, are used to processWhat equipment is used on a bauxite site? LinkedIn

How is bauxite processed? LinkedIn

TON mineral Published Jun 12, 2023 + Follow Bauxite is processed by first removing any foreign material such as trash, clay, and rocks Then, it is screened and washed to remove any debrisBauxite Efficiently remove silica and clay from bauxite ore to improve final product quality Through the introduction of a customised hydrocyclone configuration and our AquaCycle thickener technology we will: Remove silica contamination Remove clay contamination Our equipment is introduced at the clarification and classification stage ofBauxite Processing Plants CFlo CDE Asia

Mining and Refining Process International Aluminium Institute

The process stages are: 1 Milling The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the digestion stage Lime and "spent liquor" (caustic soda returned from the precipitation stage) are added at the mills to make a pumpable slurry 2Alumina, processed from the mined bauxite ore, is fed into a cell where it is mixed with cryolite, through which a DC electric current is passed Bauxite is extracted through open cast mining andHow is aluminum extracted from Bauxite ore? LinkedIn

What equipment is used in the bauxite mining process in Jamaica?

The bauxite mining process in Jamaica typically involves the use of heavyduty equipment such as excavators, trucks, bulldozers, and frontend loaders to extract and transport bauxite ore from theBauxite Ore Processing Aluminum is found in varying amounts in nature as aluminosilicates (contains aluminum, silicon, and oxygen) in various types of clay As the minerals are weathered they gradually breakdown into various forms of hydrated aluminum oxide, Al 2 O 3xH 2 O, known as bauxite The bauxite is purified by the Bayer ProcessCase Study: Conversion of Bauxite Ore to Aluminum Metal

What are the characteristics of bauxite ore and how to crush it?

1 Primary crushing: Bauxite ore is first crushed into smaller particles, typically with a jaw crusher 2 Secondary crushing: Further crushing of the ore is carried out using a cone crusher orUnlike the base metal ores, bauxite does not require complex processing because most of the bauxite mined is of an acceptable grade Ore quality can be improved by relatively simple and inexpensive processes for removing clay, known as “beneficiation”, which include washing, wet screening and mechanical or manual sortingMining and Refining Process International Aluminium Institute

Bauxite an overview ScienceDirect Topics

Bauxite (Fig 133) is formed by surface weathering of clay rocks around the tropical region and composer of aluminum oxide (Al (OH) 3 ) It contains 15%–25% aluminum and only ore used for commercial extraction for aluminum The bauxite occurs as nearsurface layers and usually mixed with clay minerals, iron oxide, and titanium dioxideRaw bauxite ores sourced from India, Guinea, Ghana, and United States were characterized and compared in terms elemental and mineral composition, fluoride adsorption affinity and capacity, surface area, and equilibrium suspension pH [24] Fig 124 shows images of each bauxite ore as received (before milling), after milling, and with Bauxite an overview ScienceDirect Topics

Bauxite: The principal ore of aluminum Geology

Bauxite is the primary ore of aluminum Almost all of the aluminum that has ever been produced has been extracted from bauxite The United States has a few small bauxite deposits but at least 99% of the bauxite used in Bauxite is the main constituent material in the aeroplane, electric, machinery, and civil toolmaking industries It is also used as an adsorbent, a catalyst in various processes, as a desiccating agent, and in the manufacturing of dental cement In road aggregates and building materials: Lateritic bauxite is often used as a constructionFeatures of bauxite, its uses, importance, and properties

THE PRACTICE OF BAUXITE ORES PROCESSING

Bauxite ores are very sticky and usually bring a high humidity ln the aluminium industry, contrary to current mineral practice, tlows are measured in a humid basis The main problem is to handle such a difficult material Wobbler feeders are used to feed lhe ROM ore to the crushers ln recent days, apron feeders are displacing themquality of the Bauxite ore The process in use is Crushing, Elutriation (Washing) and Separation of Fines China is also reporting of Baux ite Beneficiation Plants, which uses FlotationMineral Processing technologies in the Bauxite and Alumina

Bauxite Properties, Formation, Uses » geologyscience

Bauxite is a sedimentary rock mineral that is the primary source of aluminum It is formed through the weathering of aluminumrich rocks in tropical and subtropical regions The name bauxite is derived from the French village of Les Baux, where it was first discovered in 1821 by geologist Pierre Berthier Bauxite is typically Versatility: Bauxite processing and crushing equipment can be used to process a wide range of materials, including other minerals and ores This makes the equipment a valuable asset in any miningBauxite processing and crushing equipment LinkedIn

Bauxite Ore Processing Plants Bauxite Ore Processing Star

We are one of the leading project suppliers for bauxite ore plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of bauxite ore Processing plant & equipmentIndonesia introduces the bauxite ban to replicate its success in nickel processing after banning the export of raw nickel material in January 2020 According to Indonesian Chamber of Commerce and Industry chairman Arsjad Rasjid, the export value of the country’s Nickel export reached US$209 billion in 2021 and is expected to exceed Indonesia to Ban Bauxite Exports from June 2023: An Explainer

The basic process of bauxite beneficiation LZZG

Bauxite processing equipment, calcining equipment, crusher, pulverizer, classifier Bauxite properties Bauxite, also known as bauxite or bauxite, is composed of diaspore, boehmite, and gibbsite It is an ore with a Mohs hardness between 1 and 3, usually The most commonly used raw ore

- كسارات مقلع الجرانيت في الفلبين

- nataraj atta maker harmony vc 45 kg price

- الدقيقة تقنيات الألياف طحن

- تصميم نظام طحن مطحنة

- مطحنة مطرقة كاكاو 10 حصان

- por le hydraulic sawmills for sale

- سحق الحجر الصناعي بالموجات فوق الصوتية

- حجر محطم مبيعات الهاتف المحمول في السعودية

- آلات مطحنة جوز الهند المجفف

- cocaine grinder quotation

- قائمة أسعار كسارة الحجر الجيري لتايلاند

- رجل أعمال من شركة تكسير الحجر

- اسعار سيارات كسارة زلط

- jaw crusher cheek plates replacement width

- خط إنتاج حجر محطم للبيع

- الأجهزة في المحجر من الحجر الجيري

- كسارات مصنعين الناقل غرابيل في الهند

- marble marble screening equipment manufacturer

- رسالة تمهيدية لشاشة الاهتزاز

- طحن المواد النباتية

- كسارة معدنية صغيرة للبيع

- how to crush granite scraps

- البوكسيت خام الشركة المصنعة كسارة الحجر المحمول

- خط إنتاج الرمل الاصطناعي صنع خط إنتاج الرمل من شركة

- مصنعي الحزام الناقل بنغالور

- list of hammer crusherpanies in romania

- المورد الصخور البازلتية في دبي

- الكسارات المتنقلة الأسمنت

- إجراءات التشغيل طاحونة علامة

- quarrying and mining problems in india

- كتاب تصميم حزام ناقل مجاني

- أريد أن أصنع آلة طحن الجبس بطريقة سهلة وغير مكلفة

- 500 طن حجر ساعات سحق

- working methodology of pozzolana tph crusher plant in format

- انخفاض المنغنيز في فرن دوار

- خطة الصيانة الوقائية للآلة طحن

- آلة اللوح والطحن

- Precision Coordinate Grinding Machine

- مبيعات خدمات التكسير المحمولة

- عامل مطحنة ثلاث أسطوانات في إندونيسيا

- صورة لآلة مطحنة

- pebble grinding mill manufactures price

- طاحونة خام لمصنع الأسمنت كاملة

- الشركات المصنعة كسارة العراق

- كسارة دوارة ذات قدرة عالية

- flotation separator machine made in

- الصين مطحنة الحجر الشخصي

- سال سحق الصخور والطحن

- مبدأ العمل ofindian كسارة الفك كبيرة الفك

- crusher hyderabad granite

- ورق های خشک کن در رول کاغذ توالت

- ماكينات جوارب في جزائر

- جعلت منزل صخرة محطم الذهب

- german equipment manufacturer of calcite grinding

- سنتز تجهیزات طلا

- كسارة فكية الجزائر مصنعين

- معدات الطحن مطحنة الكرة

- cement grinding padang

- كسارة أستراليا EF BF BD EF BF BD

- مطحنة الكبريت للبيع في الهند

- الرأسي أثر رمح آلة محطم الصين

- vertical roller mill feature

- الفحم المحمول الموردين مخروط محطم أندونيسيا

- تصميم الخشنة مطحنة المطرقة ( )

- دستگاه خرد کردن و پردازش زغال سنگ در ایتالیا

- available used stone crusher for quarry

- سلسلة جلخ التلميع الرطب

- صنعت سیمان از نمادهای ویژو استفاده می کرد

- حول تفاصيل آلة طحن

- bottle crusher machine

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت