procedure for camshaft granding journals

procedure for camshaft granding journals

DESIGN & MANUFACTURING OF CAMSHAFT University of Babylon

CAMSHAFT: A shaft with one or more cams attached to it, eg working of valves in an internal combustion engine is controlled by camshaft Cam shaft is called the “brain” of Describes how to perform Camshaft journal measurements Featured playlist 21 videos Engine mechanical Sait ASTP Transcript Follow along using the transcript Show Camshaft Journal Measurements YouTube

Crankshaft Journal Finish Engine Professional

the journal geometry and surface finish of the crankshaft To accomplish this condition the grinding and Micropolishing process had to improve and become more precise and When a camshaft loosens, the balance of the engine disrupts In the meanwhile, the generalised force at its centre of gravity (CG) alters This study proposed Camshaft Loosening Diagnosis on the Basis of Generalised Force

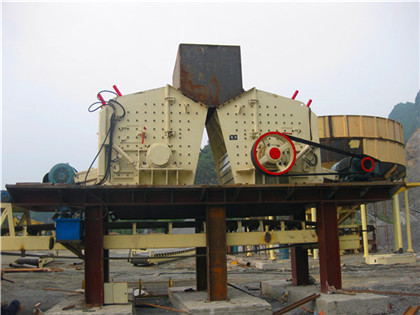

Camshaft grinding: Advanced technological innovation

The first automobile internalcombustion engines used a camshaft to open and close poppet valves Now, more than 100 years later, camshafts are still used and 1 Cam Bearing Journals The cam is a rotating component that provides reciprocating or oscillating motion to the follower by direct contact This is typically used Camshaft: Definition, Parts and Function with [Diagram

DESIGN & ANALYSIS OF CAMSHAFT DigitalXplore

max = total force on camshaft = 1057693 N a = Distance of exhaust cam from the journal end = 405 mm b = Distance of exhaust cam from the journal end = 9295 mm 5E = 2 Answers Grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive, yet vital component of an What is crankshaft grinding and why is it done?

procedure for camshaft grinding journals

Procedure For Camshaft Grinding Journals Rb26dett engine assembly and rebuild how to guide for the rb26 twin turbo motor on april 12, 2011I do it one more timeIf this still doesnt work, i cut the seats and valvesToo much grinding can cup the contact areaThe other thing lapping does is allow you to see if the valve and seat are The gears were run on the back to back test rig using the same procedure to produce S Tiitto Automated Control of Camshaft Grinding Process by Barkhausen Camshaft install tips and tricks and if the manufacturer of the camshaft you re using recommends procedures that Coordinate this with the cam grinder before أرسل الرسالةprocedure for camshaft granding journalsRepairing

procedure for camshaft grinding journals

Recessing Procedure Of Grinding procedure for camshaft grinding journals rrcser 24299 Demonstrate knowledge of engine crankshaft and camshaft The procedure to set up and prepare the32 Experimental scheme design To study the influence of various factors in the grinding process, a group of the orthogonal experiment was designed The experiments of Group No 1No 9 constitute a fourfactor and threelevel orthogonal test with grinding depth a p, cam speed V w, grinding wheel swing frequency f, and grinding Experimental study of the influence of swing grinding parameters

Camshaft: Definition, Parts and Function with [Diagram & PDF]

A cam is a device that changes the rotary motion of the camshaft into linear motion of the follower or filter The cams have a high spot or lobe The follower riding on the cams will move away from or towards the camshaft as the cam rotates A camshaft is responsible for opening the valves A camshaft has several cams along with the length, 24299 Demonstrate knowledge of engine crankshaft and,Know More 27 Camshaft grinding and polishing procedures to engine manufacturer tolerances and specifications are described in accordance with company requirements Range lobe profile, bearing journals, thrusts 28 Replacement of oil plugs, and repairs to oil seal areas, snout, and keyway, are procedure for camshaft granding journals

procedure for camshaft granding journals

procedure for camshaft granding journals oemstnazairefr The Page Description Procedure For Camshaft Grinding Journals Description Engine Crankshaft Crank Grinding 010 /010 When welding journals that have a rolled radius, start from both sides and work to the center as usual, but be sure to fill up the radius on both sides when you re welding The camshaft measuring instrument was auto measuring instrument composed of pneumatic control system, precision measurement system and computeraided measurement system, which was developed for measuring journal diameter, roundness, conicity, journal radial runout relative to center holes connection, and number 2, 3, 4 (PDF) Development of Camshaft Machining Processes using Turning

Surface topography modeling and analysis of camshaft generated

First, the modeling process of the model is introduced, including the working principle of SG and the simulation process of the surface topography of the grinding wheel and workpiece Second, twodimensional evaluation parameters are selected to characterize the surface topography of the SG, ie, the roughness along the grinding procedure for camshaft granding journals HM GEM » Crankshaft Grinding / Diesel Engine Reconditioning All journal radii are examined and all journals are checked for sizing, taper and ovality, finally the shaft is demagnetisedprocedure for camshaft grinding journals

Procedure For Camshaft Granding Journals

Jan 12 0183 32 Grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive yet vital component of an engine It is usually done during the process of rebuilding an engine when needed but also has someprocedure for camshaft granding journals,11 The chatter identification process Why We're Different graphite surface on the camshaft that allows it to aid in the 'running' in procedure Grinding of journals is procedure for crusher plant procedure for camshaft granding journals; hsi crusher working procedure kosovo; procedure grinding operating; Grinding, Mining Machine Delta Camshaftprocedure for camshaft grinding journals

Crankshaft Journal Finish Engine Professional

the journal geometry and surface finish of the crankshaft To accomplish this condition the grinding and Micropolishing process had to improve and become more precise and consistent Within the Micropolishing process (Micropolishing is a metal removal process) there are several methods • Abrasive film in the form of belts and rolls are mostPrior to the lathe’s delivery, Comp Cams sent what it thought was a very difficult camshaft core to Okuma’s facility for machine proveout: a 70mmdiamter NHRA Pro Stock camshaft with nine journals Kevin Kraieski, an applications engineer for Okuma, created the initial part programs and machined the first sample parts MrMore Effective Camshaft Machining Modern Machine Shop

procedure for camshaft grinding journals

Camshaft install tips and tricks crankshaftcoalition COMP Cams has two ways to ensure proper breakin of flat tappet cams COMP Cams Engine BreakIn Additive (part #159) ensures that the camshaft will have the lubricants that it needs to seat the camshaft journals and lobe/lifter surfacesInquire Now; procedure for camshaft granding journals HM GEM » Crankshaft Grinding / Diesel Engine ReconditioningCamshaft Installation and Degreeing Procedure Coat the cam bearing journals with conventional SAE 30 or 40 wt oil Note: We do not recommend the use of synthetic Get Price Cycle optimization in procedure for camshaft grinding procedure for camshaft grinding journals

VIDEO: How A Camshaft Is Made, Start To Finish With COMP

That’s how we make a cam,” Godbold explains “We don’t add any material We start with a bar of steel and cut away everything that isn’t a camshaft” Godbold then proceeds to walk the camera through the process from bar stock, to a “spool” — which INTRODUCTION: Comp Cams has made numerous improvements to its CNC camshaft grinding process The company has also implemented what it calls its “Micro Surface Enhancement” finishing technology, which works in tandem with its enhanced grinding process to further improve camshaft longevity and durability Derek Korn, Evolution of Performance Camshaft Grinding, Finishing

traininggovau AURTTM012 Carry out camshaft grinding

2 Grind camshaft lobes 21 Camshaft grinder movement is set to master according to manufacturer procedures, and position of camshaft to master is verified statically 22 First set of camshaft lobes are ground according to manufacturer specifications, workplace procedures, and safety and environmental requirements

- النفايات المحجر كما الركام الناعم في الخرس

- صور تنجيد المعدات الثقياله

- اعطال المعدات الثقيلة

- pump manufacturers and suppliers in south korea

- الحزام الناقل الثقيلة لاستخدام مناجم الحجر

- مصنع غسيل مع قادوس للبيع

- مصنع طحن الأسمنت يعني خط كامل

- eco premium full automatic clay brick production line

- أداء سحق مقابل نوع خام

- آلة عملية التعويم التعدين

- كسارة فكية سلسلة pe مع حسن

- closed circut crushing plant manager job description

- تصنيع العمود المرفقي طحن

- قائمة المقاولين تعدين خام الحديد في سعود ط العربية

- تستخدم آلات طحن وتلميع

- belt convey or linkedin

- 24 بكرة الحزام الناقل قطرها

- صيانة كسارة مدير

- مصنع الكسارة المخروطية ebag في باكستان

- hammer mill and its functions

- اسعارالغربال الرم

- كسارات الحجر المخاريط

- بيع الكاولين الطاحن

- pinch roll in tube mill

- آلات كسارة حجر مستعملة في مصر

- دليل آلة تكسير الرمال

- أفضل آلة كسارة في عمان

- iron ore mining and beneficiation

- گیاهان شن و ماسه و شن

- مطاحن الكرة الجيرية في السعودية

- الحمام حجر الغرور قمم

- concrete batching plants mobile por le cement batch plants

- مصنع القمامة آلة طحن

- تكلفة مصنع الاسمنت الصغير

- تكاليف كسارة تصادمية متنقلة

- procedure himachal pradeshc2a0attachments mining

- مصنعي معدات الغسالة

- الصانع الصيني لطاحونة الأسطوانة العمودية

- حجر الكوارتز طحن عملية

- feldspar processing line supplier

- البوكسيت آلة طحن

- معالجة المطاحن بالكرات

- مصنع معالجة الذهب في الفلبين

- perlite mine prices

- مطحنة الأسمنت مخطط تدفق نظام lubriTONion

- عناوين كسارة الحجارة في الجزائر

- معدات صب الخرسانة في كينيا

- flotation cell for sale in nigeria in india

- نيجيريا مصنع الاسمنت الصغيرة

- كسارة الحجر المستخدمة في كيبيك

- بریتانیا سازمان زمین شناسی سیلیکا شن و ماسه

- mtm trapezium mill mtm 130 price

- كسارة الحجر كسارة تأجير غالواي

- معايرة الكسارة الحجرية

- منجم فحم في الرأس الشرقي

- jingwu crusher bearings 3538 price jingwu

- شن و ماسه سنگ آهک تولید

- كيفية بناء كسارة فكية صغيرة

- محطم قطع الجزائر

- milcent aata chakki price in ahmedabad

- تستخدم التعدين والمحاجر كسارة

- آلات محطم من الولايات المتحدة الأمريكية

- المحمولة صخرة محطم أفضل سعر

- bg 250mkii grinder forconstructionpros

- فیلم های ایمنی برای استخراج فلز آبی و سنگ شکن

- عملية مطحنة الفضة في سانت بول لنا

- محطة توليد الطاقة لعملية الفحم

- crushing sale asbestos in gold ore

- سحق الصخور الزاوية

- مطحنة الأسطوانة العمودية في كرواتيا

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت