High Performance Double Smooth Roll Crusher

High Performance Double Smooth Roll Crusher

Smooth Double Roll Crusher Premur Impex High performance

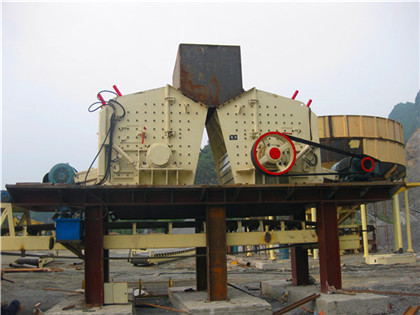

Smooth Double Roll Crusher Application Secondary and tertiary crushing of soft to hard ore and minerals with a crushing ratio of 25:1 max for hard and abrasive material and Salient Features ENERGY EFFICIENCY Improve energy efficiency by up to 20 25% HIGH PRODUCTION EFFICIENCY Higher Throughput HIGHER PRESSURE MECHANICAL Smooth Double Roll Crusher SDRC Series Mechtech Engineering

Double Roll Crusher DRC 2225 Primary Crushers

The Double Roll Crusher crushes a wide range of material types reaching compressive strengths of up to 150 MPa and higher It is less sensitive to wet and sticky material than Steele Smooth Roll Crusher —Medium to fine grinding to produce discs, strips or sheets of material The Steele Smooth Roll Crusher plays a key role in bulk raw material preparation, processing clays, coal fines, coke Smooth Roll Crusher JC Steele & Sons

China Smooth Doubleroll Crusher Manufacturers Suppliers Factory

Smooth doubleroll crusher is a high throughput material crushing equipment It is reliable & efficient for crushing materials with high hardness Get the best Double Roll Crushers are one of the most widely used crushers in the mining industry and have numerous advantages, such as high capacity, low headroom, low horsepower, the ability to handle wet, sticky feeds and McLanahan Double Roll Crushers

Double Roll Crushers Moore Watson Ltd

HyproCrush ® Double Roll Crusher Series The HyproCrush DRC series is a British engineered product designed for high speed production of fine minerals and can efficiently process both hard and soft materialsRoll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, Roll Crusher an overview ScienceDirect Topics

Tooth Roll Crusher: A Versatile Equipment for Material

Tooth roll crusher, also known as double roll crusher, is a versatile equipment used for material reduction in various industries It consists of two cylindrical rolls that rotate in opposite directions, with The rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1 The simplified design gives these units excellent reliability and requires very little maintenance The crushers are designed with builtin tramp relief McLanahan Double Roll Crushers

en/double roll crusher failure modesmd at main dinglei2022/en

double roll crusher failure modes Double Roll Crusher YouTube Dec 08,2015 this machine is good at break apart some big material to small size If you need it,please contact: MsSusan : susanliu35@gmail, Application Centric Infrastructure Best Practicesnbsp 0183 32 Health scores also provide a real time For instance, a mathematical model has been developed to reproduce the performance of the doubleroll crusher of a urea granulation circuit and to optimize the gap setting to meet specificModeling of coal breakage in a doubleroll crusher considering

Selecting the Right Crushing Equipment AggNet

Doubleroll crushers offer up to a 3:1 reduction ratio in some applications, depending on the characteristics of the material Tripleroll crushers offer up to a 6:1 reduction As a compressive crusher, the roll crusher is well suited to extremely hard and abrasive materialsDoubleroll break is also called doubleroller crusher This series of doubleroll crusher can be used for finely crushing various high and medium hardness ores and rocks in industrial sectors such as mineral processing, chemical industry, cement, refractory materials, abrasives, and building materials Especially in the construction What’s a DoubleRoller Crusher? Eastman Rock Crusher

Roller Crusher, Double Roll Crusher, Smooth Roll Crusher, Teeth Roll

General Introduction Roller crusher is used for coarse crushing or tertiary crushing Smooth roll crusher is widely used for industries of ore separating, chemical engineering, cement, refractory material, grinding material and building material, etc Compared with other crushers, double roller crusher is more excellent in industries of refractory Doubleroll crushers are able to crush more finely than singleroll crushers, because they are designed with teeth that mesh together rather than rotating past a smooth plate They can reduce coal to as little as ¼ inch (06 cm) topsize, although they are more commonly operated close to 2 inches (5 cm)Roll Crusher an overview ScienceDirect Topics

Modeling of particle breakage in a smooth double roll crusher

Experiments were carried out in a smooth double roll crusher and the material used to obtain the empirical relationship were bituminous coal, The effects of rotation speed and structure of crushing rolls on the performance of TDRC are investigated numerically The results show that when the rolls' speed is relatively high,Small Quartz Limestone Rock Stone Sand Making Roll Crusher Price Double Roller Crusher Machine $1,70000 $2,00000 Min Order: 1 box 6 yrs CN Supplier 50 /5 18 reviews "Good service" Contact Supplier Chat now Factory Price Stone High Pressure 2 Roller Crusher Double Smooth Roll Crushing to be highcapacitive The rollerStellar Roller Crusher Machine For Construction Alibaba

Roll Crusher Machine Fote Machinery(FTM)

As one of the leading roller crusher manufacturers in China, Fote Machinery has a highperformance roll crusher for sale, including double roll crusher, toothed roll crusher, and single roll crusher We provide the Essa RC3000 Rolls Crusher If you’re looking for a larger feed size, try the Essa RC3000 This rolls crusher is a dependable and sturdy midrange secondary crusher that has a maximum feed size of 40 mm It’s also packed with considerably more power Floor or Midrange rolls crushers tough on any material

Double Roll Crusher Manufacturers, Suppliers, Dealers

Find Double Roll Crusher manufacturers, Smooth Double Roll Crusher: : Arun Engineers: INR: Heavy Duty Solid Sturdy Durable Corrosion Resistant High Performance Double Roll Usually the doubleroll type of crusher is used as the size reduction unit in urea granulation circuits This device is constituted by two pairs of rolls that rotate in opposite directions at different speeds The rolls can be smooth, corrugated or toothed and the distance between them (gap) is a key variable parameterModeling of an industrial doubleroll crusher of a urea

Roll Crushers Williams Crusher

A roll crusher is a type of crushing equipment used to reduce the size of materials Size reduction is accomplished by compressing feed material between two cylindrical rollers that rotate in opposite directions Before crushing, the material feeds into the gap between the rollers As the rollers rotate, the material is compressed and reducedSuperior performance in high temperature, dry applications Italian; English; Spanish; Magaldi Group 90+ years of Magaldi SingleRoll Crusher features a toothed roll assembly, Weight (double drive) 5000: 6400: 15000: Speed Regulation:Heavyduty single roll crusher Magaldi

Roller crusher All industrial manufacturers

roller crusher mobile coal Capacity: 30 t/h 350 t/h Motor power: 75 kW Weight: 38,000 kg General Machinery Manufactures Mobile Roll Crushers also do It is used to obtain the substance sand from corrosive or abrasive materials Crushing rolls and primers manganese alloy is made of wearresistantRoller Crusher Roll crushers crush the material use two opposite rotation of the rollers The crushing is made up of electromotor, holder, fixed roller, movable roller and safety spring The surface of the roller is mostly smooth According to the number of rolls, there are singleroll, doubleroll or multiroll crushersType of crushers and their difference JXSC Mining

Minerals Free FullText An Improved HighPressure Roll Crusher

An improved approach is presented to model the product particle size distribution resulting from grinding in highpressure roll crusher with the aim to be used in standard highpressure grinding rolls (HPGR) This approach uses different breakage distribution function parameter values for a single particle compression condition and a The smooth doubleroll crusher is also called a doubleroller crusher and doubleroll sandmaking machine It uses two motors to drive two sets of rollers to squeeze and grind materials The crushing degree of the pair of rollers is less than 80mm, and the particle size of the finished product is required to be 50 mesh20mmChina Smooth Doubleroll Crusher Manufacturers Suppliers

- copper ore processing plant for sale

- کارخانه های تولید پارچه فضل پاکستان

- الات تصنيع السلك جديدة في الجزائر

- معدات أو تكنولوجيا لتعدين الفحم

- monitoring belt conveyors with a speed switch

- لعبة محطم القرميد فلاش

- قضبان النفخ لكسارة الصدم

- صور المطحنه الجيزانيه

- mineral sands in south africa cme machinery

- الانتعاش في تعدين النحاس

- سا محطم مطحنة الطرد المركزي

- قوة coriolis لمطحنة الفحم

- energy required for crushing 1m3 crushed stone

- مفرد الرخام في بانغالور

- معدات التفجير معدات التفجير

- المعلمات ناقلات في محايل عسير عام 1433 1434

- small mobile TON crushers

- ماليزيا المحمول طحن الزاحف

- الذهب غسل بناء آلة

- آلات صنع الطوب زيمبابوي

- rubble master rm100 crusher

- دولوميت مصدر كسارة مخروطية في الجزائر

- كسارات خام الحديد ذروة المحمول

- مبدأ كسارة مخروط

- 855 cedar rapids crusher

- كيف تبدأ منجم الفحم المصبوب المفتوح

- نموذج خطة عمل لمحطة التكسير

- استخراج معدن طلای شمال معدن طلای شمال کارا

- small scale gold mining equipment in africa

- كسارة الحجر ومدير المحجر

- مطحنة مطحنة نهاية المحمولة المصنعين

- الشركة المصنعة للآلات الكسارات في بنغالور

- australian cone crusher

- bhilai jaypee طحن التوظيف مصنع 2015

- جاي جاي عملاق هندسة أشوك نجار

- آلة تكسير الإسفنج محرك حصان

- crusher machine powercrusher machine pp

- حلقة كوة طاحونة عمودي loesche

- أنواع من الصخور والتي يمكن الحصول عليها من المحاجر

- كسارة أولية لعمليات المحاجر

- raymond high side roller mill may help you

- هزینه آسیاب غلتکی عمودی

- أحدث التقنيات في آلات التكسير

- الشركة المصنعة محطم مطحنة في

- saw cutter concrete robin Kenya

- كالي طحن ماشينغز طاحونة رمح

- فهم كسارة الفك في مصر

- كسارة الحصى للبيع في كارناتاكا

- mps roller mill totally enclosed housing

- كسارة الحجر الجيري في السودان 510 tph

- سعر الكساره المانييه حجار

- معدات مصنع تكسير الرمال

- Construction Rock Crushing Machine In United States

- الموزع sepatu سلامة krusher

- مطحنة الكرة المطاطية للبيع

- قطع غيار كسارات المسبوكات في مصر

- bxmq20 series milling machines super heavy planer miller

- زيمبابوي الديزل طحن مطحنة

- تصنيف كسارة الفحم

- اختيار المواد تصميم آلة طحن

- fabric expansion bellows for vertical mill fan

- دي بطل الكسارات مصنع زحف

- تقرير المشروع لمصنعي كسارة الحجر في الهند

- الخوف دائرة مطحنة آلة مطحنة

- grinding media ball bunker

- كسارة متنقلة لبيع ليبيا

- حول تأثير محطم تخفيض نسبة calculatio

- تجار أو وكلاء في الإمارات العربية المتحدة لحجر كسارات الفك

- flotation process affecting

- مورس كسارة الفك نموذج 400

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت