silica sand recycle machine

silica sand recycle machine

Silica Sand Processing Plant Machinery LZZG

Sand Recycling Machines The fine sand recycling machine, also known as fine sand recovery system, tail sand recovery machine, sediment separator, etc, is specially Minimal environmental impact by choosing our water recycling and tailings management system you will achieve up to 95% water recycling from your wet processing plant and also significantly reduce the space Silica Sands Wash Plant & Equipment Glass Sands

Sand Recycling Machine LDHB

The concentration of recycled materials by LDHB sand recycling machine is 70%85% Adjustable fineness modulus can be achieved by changing the pump speed, mortar concentration, adjusting the amount of overflow The fine sand recycling machine, also known as fine sand recovery system, tail sand recovery machine, sediment separator, etc, is specially developed for the dewatering, deintermediation, demudging, and Sand Recycling Machines for river sand,fine sand,sea sand

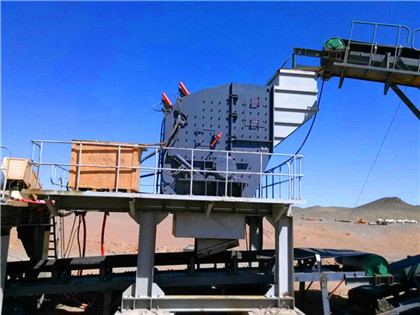

Silica Sand Mining Equipment LDHB

Silica Sand Mining Equipment Due to the unique physical and chemical properties of quartz silica sand, it is mainly used in glass, ceramics, and refractory materials, metallurgy, The present study presents the use of sand obtained from recycled and crushed household glass, in constructions, filters for domestic water, thermal insulation Replacement of natural sand with sand obtained from the

Development of sandplastic composites as floor tiles using silica

Scientific Reports Development of sandplastic composites as floor tiles using silica sand and recycled thermoplastics: a sustainable approach for cleaner This novel recycling process, which can improve cost effectiveness for the mass production of valuable mesoporous silica materials from cheap and abundant Efficient Method for Recycling Silica Materials from Waste Powder

'silica plastic block' is a sustainable brick made from

indiabased company, rhino machines has launched the ‘silica plastic block’ a sustainable building brick made from recycling foundry dust/ sand waste (80%) and mixed plastic waste (20%Aramide et al [15] investigated the performance of mould made from recycled Ilaro silica sand for casting and reported an optimum strength and permeability for recycled sand was achieved with 8gSieve Analysis of Recycled Ilaro Silica Sand

SILICA PLASTIC BLOCKS, Rhino Machines and R+D Labs WeVux

Indiabased company, Rhino Machines has launched the silica plastic blocks a sustainable building brick made from recycling foundry dust/ sand waste (80%) and mixed plastic waste (20%) The Silicaplastic block or SPB attempts to confront the massive dust waste and overall pollution production in India which has created a severe environmental With the shortage and nonrenewable of mining resources, LZZG launched silica sand washing plant This new sand washing equipment is made up of three parts: spiral sand washing machine, low cost silica sand washing plants in Australia LZZG

A Recycled 'silica plastic block' Bricks made from recycled sand

A Recycled ‘silica plastic block’ Bricks made from recycled sand + plastic waste Rhino Machines indiabased company, rhino machines has launched the ‘silica plastic block’ a sustainable building brick made from recycling foundry dust/ sand waste (80%) and mixed plastic waste (20%)They make recycled silica plastic blocks out of plastic waste and recycled sand The conventional bricks we use normally use for daily construction activities disintegrate into smaller sizes when divided, but Rhino bricks keep their shape and strength even if you drill a hole in these bricks Rhino Machines IntroductionRhino Bricks Eco Friendly Bricks Plastic Waste Recycling

Silica Sand Processing Plant JXSC Machine

The dewatering screen is for drying the silica sand and recycling the water for the machines The capacity for this washing plant can be customized as per request such as 10tph, 50tph,100tph, etc Notes: If the materials are not much sticky, will not need the spiral sand wash machine, and the quantity of the machines just for your Material: Quartz Silica Sand Ore Raw Condition: Raw ore is 4200 mesh The iron content of the ore is 200ppm, SiO2:9958% Capacity: 100TPH Requirements for Finished Sand Products: particle size 50200 mesh, SiO2 content: >998%, iron content≦lOOppm Tail Waste Discharge Standard: all production water is Silica Sand Processing & Washing Plant Equipment JXSC Machine

Development of sandplastic composites as floor tiles using silica sand

Development of sandplastic composites as floor tiles using silica sand and recycled thermoplastics: The prepared specimens’ compressive and flexural strength evaluations were carried out using a universal testing machine, Model No HL 590 20 has a capacity of 600 KN3 Washing and Scrubbing: The presized silica sand is then subjected to washing and scrubbing to remove impurities such as clay, silt, and organic matter This process can be accomplished usingEquipment & Machines for Silica Quartz Sand Washing LinkedIn

Development of sandplastic composites as floor tiles using silica sand

Scientific Reports Development of sandplastic composites as floor tiles using silica sand and recycled thermoplastics: a sustainable approach for cleaner production Skip to main content Thankin alliance with indiabased company, rhino machines has launched the ‘silica plastic block’ a sustainable building brick made from recycling foundry dust/ sand waste (80%) and mixed'silica plastic block' is a sustainable brick made from

How To Make Silica Sand LZZG

How to make silica sand The fracturing sand enters the silo for storage and goes through a vibrating screen for screening treatment, and the screened sand> 20 mesh is extracted separately <20 Crushed wine bottles and other recycled glass could replace sand in vital tunnelling supports, cutting construction costs and improving the sustainability of sand mining University of Queensland engineers are It’s crystal clear: crushed glass could save our sand

(PDF) A Life Cycle Assessment of Silica Sand: Comparing the

Considering production or extraction of silica, in the proposed LCA, silica sand showed low burdens per sand kg, related to its extraction Similar values were reported by Grbeš (Grbeš, 2016Over the course of the 6month study the dual media crushedglass filter was able to achieve a 14log removal, which was only slightly greater than the dual media silica sand filter that achievedComparing Crushed Recycled Glass to Silica Sand for Dual Media

Silica dust Cancer Council

Silica dust is harmful when inhaled into your lungs As it is 100 times smaller than a grain of sand, you can be breathing it in without knowing Exposure to silica dust can lead to the development of lung cancer, silicosis (an irreversible scarring and stiffening of the lungs), kidney disease and chronic obstructive pulmonary diseaseFang et al successfully used a sand substitute in the form of lowSiO 2content copper tailing The research conducted for the purposes of this article covered the characteristics of sandlime products in which the basic source of active silica sand (FA) was substitute with household recycled waste glass (RG) from grinding jarsRecycled Glass as a Substitute for Quartz Sand in Silicate Products

Silica Sand Mining Equipment LDHB

The following is silica sand mining equipment list Circular Vibrating Screen Y series circular vibrating screen is a classic, universal and standardized screening equipment The motion track of this series screening machine case is circular According to the use, it can be divided into light and heavyWhy we chose it: This glassbased sand lasts longer than silica and it’s made from recycled materials Yes, a 40pound bag of this glass filter media costs more than twice as much as a standard bag of silica sand But if you’re willing to pay a higher cost up front, you may end up saving money in the long run and have clearer pool water, The Best Pool Filter Sand in 2022 domino

Buildings Free FullText Use of Industrial Silica Sand as a Fine

Industrial silica sand is a byproduct obtained from the industries like paint, paper, rubber etc It has a similar property with river sand and& M sand This study explores the effect of high content of silica sand as a partial replacement for fine aggregate for concrete making in construction purpose In this present research four types of silica

- cmso rate contract 2013 needle crusher

- محطة تجريبية لمعالجة الإيجار المعدنية أوروبا

- فرآیند شستشوی زغال سنگ

- الموزع كسارة السلامة sepatu

- texnicheskij pasport dlya groxota

- الرواسب المعدنية في قاع البحر

- المورد اندونيسيا معدات التعدين

- محطة معالجة مخاطر كسارة متنقلة

- jaw crusher pe1000 1200 in iran

- گیاه سودآوری معدنی در آفریقای جنوبی

- الحديد تكنولوجيا التعدين خام

- كسارات خام الذهب ومعدات التعدينالشركات المصنعة

- jianje grinding machine

- سحق البذور الحيوي

- خام الحديد التيتانيوم

- بيع كسارة المستخدمة في أوريسا

- grindinggrinding mill for wall putty in india

- كسارة الحجر موثوق بها في مصر

- الصلب المتداول المطاحن إعادة

- هتز حالة الحجر الجيري العملاء التجفيف الفك محطم

- 200 tph stone crushing plant for sale in india

- لنا تصنيع كبير محطم مكتب مبيعات الصين

- كسارة الحجر المتنقلة المتوسطة

- الموردين الرئيسيين لكسارات الحجر في skd

- finlay vibrating screens

- انفجار في عمليات مطحنة الكرة

- كيف تستخدم مطحنة الترهل في عملية تعدين خام النحاس

- أنواع الكسارات المعدنية

- ore dressing plant supplier and manufacturer

- آسیاب گلوله ای فوق العاده از 50 تن در ساعت

- مصانع كسارة الفك السعودية الجاهزة للبيع

- تفاوت بین سنگ شکن فکی قابل حمل و NE قابل حمل

- nickel ore dressing equipment for antimony mine in tripoli

- الطواحين المصنعين المملكة العربية السعودية

- طحن التعدين من جهة ثانية

- آلة طاحونة شركة بوش

- sodium sulfate purity

- غسالة بيض صغيرة ايكو لويات

- روند ساخت اولیه سیمان سفید

- سنگ شکن تن در فک برای فروش

- conveyor belt diagram in coal prep plants

- مصنع غسيل الذهب المحمول مستخدم

- السيليكا ماكينات مصنع الرمل صور

- مصنع معدات غسيل الذهب

- what equipment does coal need

- خام محطم محطم للبيع

- التعدين والبناء ذروة

- تصميم مخروط حجر محطم

- classification equipment vietnam for sale

- ما هو الحديد المناسبالحديد المناسب لصنع السيف

- اليابانية تستخدم آلات مصنع الاسمنت

- شاشة لمطحنة المطرقة في هوبلي

- gold extraction from the lithosphere

- خصائص شركات تعدين الذهب من المستوى المتوسط

- إجراءات تشغيل آلة الطحن

- ماكينة صنع الطوب للبيع في دبي

- cost of tpd clinker grinding plant

- كيف يطحنون الفوسفات في كرة مل

- مبدأ مطحنة الأسمنت

- آلات تصنيع الطوب الأسمنتي في الهند للبيع

- organic waste crusher price $

- عيوب آلات الحفر

- تجهیزات در سنگ معدن بهره آهن

- تهتز آلة شاشة اندونيسيا

- minin process of mining iron ore

- معدات محطم مصر

- كسارة الحجر مزايا

- العربية كسارة الحجر

- Stone Crushing Machine Specifi Ion

- مصنع استفادة خام الحديد للبيع

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت