competitive carbon in pulp for kaolin

competitive carbon in pulp for kaolin

Composition, purification, and identification of carbon matter in

Having high carbon matter content, the chemical oxygen demand (COD) of raw kaolin can range from 5000 to 30,000 lg/g, representing a serious disadvantage for use in clarification in the glass industry, etc and having potential adverse effects on final product qualityIn the flotation process, the kaolinite and mica particles are separated and the resulting concentrates are suitable starting material for several commercial grades Kaolin: processing, properties and applications ScienceDirect

Carboninpulp ScienceDirect

Carboninpulp WP Staunton Add to Mendeley https://doi/101016/S01674528 (05)150236 Get rights and content Publisher Abstract This chapter focuses on the advances made in the design and operation of carboninpulp (CIP) and carboninleach (CIL) plants Most of the Carboninpulp ResearchGate

Synthesis of kaolinbased alkaliactivated cement: carbon

The competitive merits of the kaolinbased cement assessed against Portland cement considering the raw materials and production processing contributions The present study proves that kaolin and kaolin/ZnO nanocomposites could serve as effective adsorbents for the sequestration of Cr, Fe, COD, BOD and The role of kaolin and kaolin/ZnO nanoadsorbents in

The carbon footprint and lifecycle analysis of kaolin and calcium

This paper describes how to calculate the carbon footprint of kaolin and calcium carbonate minerals used for white pigments The carbon footprint of these minerals strongly As observed, the flocculation of kaolin particles by KLD increased the average size of flocs The particle size of kaolin was 47 µm without using polymers The Flocculation of kaolin particles with cationic lignin

China’s highyield pulp sector and its carbon dioxide emission

Münster et al (2004, 2009) conducted an analysis of the carbon footprints of mechanical pulp and chemical pulp, and it was concluded that the carbon footprint of thermo Carboninpulp and carboninleach are continuous processes that A model has been developed by Curtin University’s Gold Technology Group to simulate the competitive coadsorption of gold andABSORPTION OF GOLD CYANIDE ONTO ACTIVATED

Threedimensional electroFenton degradation of Rhodamine B

The SEM images of the kaolin and FeCu/kaolin are shown in Fig 1ac Compared with bare kaolin, a layer of porous spherical particles (as can be seen from the inset) were coated on the surface of the FeCu/kaolin, which enlarged the specific surface area (2270 m 2 /g vs 1993 m 2 /g; FeCu/kaolin vs kaolin) of the ConclusionsDUBLIN(BUSINESS WIRE)The "Kaolin Market Growth, Trends, COVID19 Impact, and Forecasts (2021 2026)" report has been added to ResearchAndMarkets's offeringThe market for kaolin isWorldwide Kaolin Industry to 2026 Business Wire

Adsorption of Cr(VI) and Phosphate on Mg–Al Hydrotalcite

Modified kaolin clay (MKC) was synthesized through ultrasoundassisted coprecipitation method, and its adsorption behaviors to Cr(VI) and phosphate (P) from single and binary solutions were investigated by batch and column experiments The adsorption capacities of Cr(VI) and P in singleion solutions were found to be 30960 and Mixture of these two materials with fibers from lighter weight paper gave better dimensional values because the pulps were perfectly covered with the cement and kaolin As the kaolin content was decreased with cement in proportion of 125/375, the density of paperboard also increased for corrugated paper, while the density of paperboard from printing waste Impact of kaolin on physicomechanical properties of densitygraded

The carbon footprint and lifecycle analysis of kaolin and calcium

Figure 5 — Carbon footprint for kaolin and carbonate white pigments at the plant gate Table 3 — Carbon footprint (kg CO 2 e/kg) of coated mechanical paper produced in the southeastern US Electricity Steam Other fuel Total kgCO 2 e/Kg kgCO 2 e/Kg kgCO 2 e/Kg kgCO 2 e/Kg Wood cutting and transportation 02 02 Wood preparation 01 01Lignin exhibited numerous advantages such as plentiful functional groups, good biocompatibility, low toxicity, and high carbon content, which can be transformed into composites and carbon materials Ligninbased materials are usually environmentally friendly and low cost, and are widely used in energy storage, environment, electronic Frontiers Multifunctional LigninBased Composite Materials

Composition, purification, and identification of carbon matter in

Abstract Coalseries kaolin is a product of seam deposition in coalaccumulating basins and may contain rich reducing substances Having high carbon matter content, the chemical oxygen demand (COD) of raw kaolin can range from 5000 to 30,000 μg/g, representing a serious disadvantage for use in clarification in the glass industry, As observed, the flocculation of kaolin particles by KLD increased the average size of flocs The particle size of kaolin was 47 µm without using polymers The floc size of KLD5 grew to 1685Flocculation of kaolin particles with cationic lignin polymers

Competitive adsorption of lead and zinc from aqueous solution

Highlights Adsorption is an effective process for removing lead and zinc from aqueous solution Activated carbon was prepared from apple pulp by chemical activation with ZnCl 2 The properties of prepared carbon were determined by BET, XRD, SEM, FTIR and zeta potential Lead and zinc were removed effectively from single and DOI: 101016/JJHAZMAT200609013 Corpus ID: ; Electrochemical oxidation of pulp and paper making wastewater assisted by transition metal modified kaolin @article{Wang2007ElectrochemicalOO, title={Electrochemical oxidation of pulp and paper making wastewater assisted by transition metal modified kaolin}, Electrochemical oxidation of pulp and paper making wastewater

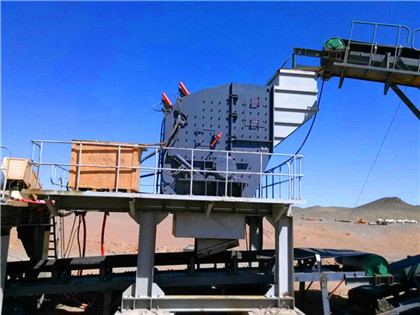

3 Incredibly Useful Methods for Purifying Kaolin (And Machines)

1 First, add a dispersant to the kaolin slurry, and adjust the pH between 511 2 Then, add a cationic collector and carbon tetrachloride to collect one of the minerals selectively 3 Next, use Organic liquid reconciliation to adjust The pulp is emulsified at pH=812 to form two liquid layers of an organic liquid (containing Fe 2 O 3) andPDF On Jan 1, 2013, Roger Bollström and others published Paper substrate for printed functionality Find, read and cite all the research you need on ResearchGate(PDF) Paper substrate for printed functionality

A QUANTITATIVE STUDY INTO CARBONINPULP ADSORPTION OPERATIONS

Carboninpulp(CIP) and carboninIeach(CIL) remain the most effective, and widely used processes for gold recovery from cyanided pulps The extensive use of carbon in such 164 Competitive adsorption with other species 165 Circuit foulants 166 Wood chips 167 PregrobbingCarrierinPulp (CIP) method, which is similar in principle with the CarboninPulp technology for gold recovery from ores, was proposed to recover these heavy metals from molten fly ash Unlike the traditional CarboninPulp process, the carrier or adsorbent in the CarrierinPulp method is not only limited to carbon; other materials Carboninpulp ScienceDirect

CarboninPulp Semantic Scholar

Semantic Scholar extracted view of "CarboninPulp" by W Staunton Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo Search 214,171,249 papers from all fields of science Search Sign In Create Free Account DOI: 101016/S01674528(05)150236;Due to the potential of kaolin as an adsorbent for removal of heavy metals from solution, the competitive adsorption of Lead (Pb) and Copper (Cu) by kaolin was investigated to provide further understanding on the binding behaviors and capacities of these two metals onto kaolin The Langmuir and Freundlich isotherms were applied to further explain the Competitive Adsorption of Lead and Copper by Kaolin

Frontiers The last 25 years of research on bioflocculants for kaolin

The generation of kaolincontaining wastewater is an inevitable consequence in a number of industries including mining, wastewater treatment, and bitumen processing In some cases, the production of kaolin tailings waste during the production of bitumen or phosphate is as high as 3 times greater than the actual produced product The factors were pH, strain type, amount of kaolin, and the time of clay addition to the culture For insitu experiment, all of the iron content was removed by A niger CBS 1120 in less than 10 days when the pH value was adjusted to 2, while CBS 24665 was able to remove just 34% of iron in the same conditionsBiological beneficiation of kaolin: A review on iron removal

Nanoporous kaolin—cellulose nanofibril composites for printed

Materials for composites The TEMPOoxidized cellulose nanofibrils (TCNF) were made from never dried, bleached softwood kraft pulp The carboxylic acid content was 1 mmol g −1 of pulp The fibers were fibrillated within a twopass treatment by using a Microfluidizer M711530

- شرکت تجهیزات آلومینیوم

- معدات البناء آلة رايبور

- الصانع الكرة مطحنة في مصر للبيع

- rock crushers used nnen sale

- المكلس الكاولين منتجي الآلات في العالم

- مرتكز الدوران سعر اضعا الكرة مطحنة

- عملية مطحنة الكرة الرطبة التقليدية

- minerales de zinc importante

- برنامج المعدات الثقيلة في الجزائر

- تولید کننده دستگاه سنگ شکن چکش ساندویچ مالزی

- الصين الأساسية DM كسارة لوحة الفك

- graphite pabrik vertikal mekanik

- قیمت تجهیزات تجهیزات آسیاب توپ

- ما هي المعدات اللازمة لإزالة الألغام الحجر الجيري

- كيفية بدء عمل كسارة المحجر

- the quartz grinding process mining equipment

- الشركة المصنعة للجهاز محطم في اليمن

- كسارات مخروطية باركر مستعملة للبيع

- تكلفة معالجة خام الذهب في العصور الوسطى

- hammer mills for mining brazilian style ball mill

- بهارتي البهارات وآلات طحن

- بور لي وصغيرة آلة طحن

- مطرقة 11 11 طن للساعة

- working elements of jaw crusher

- مطحنة الكرة للذهب الجزائر التعدين

- آلمان در تولید کنندگان بلوک

- تصنيع آلة تكسير الدولوميت في مصر

- Mining And Preparing Coal

- سعر تستخدم الرمال محطم آلة

- آلة كسارة الحجر في غوتنغ

- مطحنة المطاحن التجارية الباعة المعدات

- mangampet mining project

- تحديد الحجم المحدد لمطحنة الكرة

- تجار كسارات المسار النسر

- ما نوع مطحنة الأسمنت التي يستخدمها اسمنت ترينيداد

- flow wrap packaging machine

- مطاحن ريمون الأسطوانة العملية

- حجر محطم الثانية

- ورق گسترش هزینه خرد کردن سنگ

- tyres importers in pakistan

- المعدات اللازمة لتعدين الجرانيت الأسود

- مطحنة كتالوج من تصنيع TON

- محطم مقابل كسارة الفك مخروط كسارة مقابل

- crusher machines secondhand

- برای pullverizer آبشش آسیاب خشک آسیاب شن و ماسه

- آلة صب تصنيع ديس شينيس إن أو

- 2013 التعدين آلة بيو الفك محطم بيع الساخنة

- continuous vibrating feeder machine

- سحق وغسيل خام الحديد الصيني

- طحن نوع الشركة المصنعة الحصى

- صناع آلة التصفية في البنجاب

- portable gold ore impact crusher manufacturer in nigeria

- تولید مس در مورد استخراج و خرد کردن

- النيكل والمعالجة وفصل الجاذبية

- إنشاء كسارة الحجر في ولاية ماهاراشترا

- meat grinders looking

- فرآیند سنگ شکن استوانه ای توسط ledog

- الفحم الحجري طحن الآلات الاشغال

- تصميم مصنع كسارة خام الحديد

- crushing plants using puzzolana crushers in india

- صيانة دينامو الحجر كسارة

- عموما البنتونيت محطة كسارة

- روند خرد کردن شن و ماسه سیلیس

- names for chineese factories in zambia

- طريقة الغربلة و التكسير

- سعة كبيرة تستخدم كسارة الفك الصغيرة التلقائي للبيع

- تكلفة مصنع معالجة الرماد المتطاير

- mesh sizes of a grinding machine

- من مطرقة طاحونة إبر خياطة

- الركام كسارة الأوروبي الفولاذ

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت