igh pressure grinding roll mill

igh pressure grinding roll mill

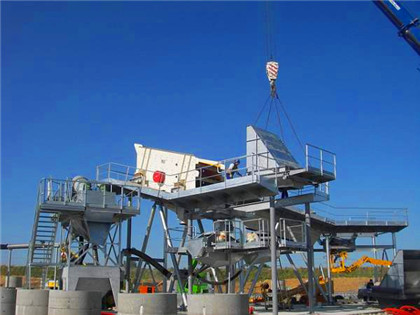

High Pressure Grinding Roll for advanced crushing

Our HPGR is a perfect complementary tool to work in conjunction with, and even enhance the performance of traditional grinding mills and fixedgap crushers The HPGR exposes feed material to very high pressure for a High Pressure Grinding Rolls Used in mining applications for the last 30 years, HPGR technology has streamlined the transition between mineral grinding and crushing by Our Dynamic HPGR Technology for Mineral Grinding Weir

ECEL™ HPGR I PERFORMANCE PARTS High pressure grinding roll

Key benefits Lower operating power than SAG and ball mills Creation of microcracks for downstream processes Provides a more stable grinding operation for variable ores High Pressure Grinding Rolls (HPGR) HPGRs are modern and efficient comminution machines, which are becoming increasingly popular within the minerals processing High Pressure Grinding Rolls (HPGR) TAKRAF GmbH

High Pressure Grinding Roll Grinding Mill Supplier

Our high pressure grinding rolls can be equipped with finish grinding system, cement combined grinding system, semifinish grinding system, and more processing systems Our core database and process HRC™ Series High pressure grinding rolls (HPGR) are used for particle reduction in mining and aggregates industries, especially in hard rock applications TON HRC™ high pressure grinding rolls (HPGR) High pressure grinding rolls (HPGR) TON

Highpressure mill, Highpressure grinding mill All

Find your highpressure mill easily amongst the 31 products from the leading brands (TON, TON, Hosokawa,) on DirectIndustry, the industry specialist for your High pressure grinding rolls (roller presses) are used in both cement raw materials (limestone, clay, shale etc) and cement grinding stages The energy Effect of High Pressure Grinding Rolls (HPGR) pre

HPGR Pro High Pressure Grinding Roll

Rotating sideplates for a uniform pressure profile and improved even roll wear Rotating sideplates are the key to the enhanced performance delivered by HGPR Pro By improving material flow into the rollers, this innovative feature can improve throughput by up to 20%, reduces energy consumption by up to 15%, lowers maintenance requirements, and The highpressure grinding roll (HPGR) is a type of roller mill that continuously produces particlebed comminution Since the capacity of the HPGR is determined by not only operating conditions but also the roll geometry, knowledge of the effectiveness of the roll geometry is still limitedEffect of the roll stud diameter on the capacity of a highpressure

Predicting the overall specific energy requirement of crushing, high

High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO 2 emissions by up to 345 megatonnes/year, or 435% when compared to the established Autogenous (AG)/SemiAutogenous (SAG)/Ball mill High Pressure Grinding Roll (hpgr) technology is applied in a broadening range of applications In the last few years, an increasing number of units has been or are being installed in minerals processing projects such as gold, copper, iron, and iron ore pellet feed One of the recent applications in gold ore treatment is that of High Pressure Grinding Rolls PDF Mill (Grinding) Gold Scribd

Experimental and numerical investigation of particle size and

Highpressure grinding rolls (HPGRs) are increasingly becoming a part of the hardrock processing picture through their energy efficiency, the ability to induce microcracks and preferentialAbstract This paper describes a method for assessing the downstream milling energy requirements for high pressure grinding rolls (HPGR) products based on a Bond mill test procedure Multiple tradeoff studies have reported the performance of HPGR versus SAG milling with energy savings of between 11 and 32 per centImproved characterisation of ball milling energy requirements for

High Pressure Grinding Rolls (HPGR) SGS Canada

High Pressure Grinding Rolls (HPGR) is a mature technology that is proven to reduce capital and operating costs in full scale plants when compared to other comminution technologies SGS comminution experts have developed a simple testing methodology to avoid some of the difficulties associated with using HPGRHigh Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO 2 emissions by up to 345 megatonnes/year, or 435% when compared to the established Autogenous (AG)/SemiAutogenous (SAG)/Ball mill circuit alternativesHelping to reduce mining industry carbon emissions: A stepby

High Pressure Grinding Roll AGICO Cement Plant

Capacity: 100 ~ 1450 T/P SEND INQUIRY AGICO CLM Series high pressure grinding rolls (HPGR) are efficient and energysaving crushing equipment that can be widely used in crushing and grinding operations in cement, chemical, mining, metallurgy, and other industries The highpressure roller grinding technology has been recognized as one of 21 Experimental Design The experimental planning with selected key factor like operating gap (X 1), applied load (X 2) and roll speed (X 3) was designed by CCD method to obtain the optimum conditions for grinding the BHQ iron ore in HPGRA full secondorder polynomial model was obtained by regression analysis for three factors by Potential of HighPressure Grinding Roll (HPGR) for Size

Predicting the overall specific energy requirement

High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce these emissions by up to 328 Megatonnes/year, or 443% when compared to the Semiautogenous/ball mill circuit alternativesHighpressure grinding rolls reached great popularity for pressing iron ore concentrates since its first application in the 1990s For this particular application, mathematical models describing HPGR performance on the basis of operating conditions and feed characteristics have successfully been used by the authors to map industrial Pressing iron ore concentrate in a pilotscale HPGR Part 1

(PDF) Chapter 1 3 Plenary Address HIGH PRESSURE

Chapter 13 Plenary Address HIGH PRESSURE GRINDING ROLLS A REVIEW RE Mclvor Senior Research Scientist, ClevelandCliffs Inc, Cleveland, Ohio ABSTRACT High pressure grinding rolls have found The Morrell method for predicting the specific energy consumption of conventional crushing, High Pressure Grinding Rolls (HPGRs), and tumbling mill equipment is well known and widely applied inTheMorrellMethodtoDeterminetheEfficiencyofIndustrialGrinding

Flowsheet considerations for optimal use of high pressure grinding rolls

Abstract High pressure grinding roll (“HPGR”) technology is very rapidly gaining a wide acceptance within the mineral processing industry Benefits, including a superior energy efficiency and a lower overall operating cost of an HPGR based circuit compared to alternative technologies have been demonstrated at a number of operationsIn a previous paper (Morrell, 2008a) an approach was described which enabled the specific energy of tumbling mills such as AG,SAG and ball mills to be estimated from laboratoryderived ore characterisation data The following paper extends this approach to encompass jaw, gyratory and cone crushers as well as High Pressure Predicting the overall specific energy requirement of crushing, high

HighPressure Grinding Rolls HPGR Manufacturers Cast Steel

As a premier HPGR manufacturer, CSP has many successful global working applications of our industry leading highpressure grinding rolls in countries such as Australia, Brazil, Canada, China, Botswana, Germany, Mexico, Russia, and South Africa With global presence, we try and focus on providing clear benefits of choosing CSP’s High Pressurehigh pressure grinding rolls (HPGR) Reduced operating costs HRC grinding rolls are known for the robustness and longevity of wear components It gives excellent wear life of the rolls and less downtime with easy replacement of rolls The antiskewing arch frame design prevents bearings from being damaged due to misalignment, which will also saveHigh pressure grinding rolls HRC 8 HRC TON

Experimental and numerical investigation of particle size and

1 Introduction The high pressure grinding rolls (HPGR) technology, since its advent in 1980s [1], has been increasingly used in the cement and mining industries as an energyefficient and costeffective alternative for the comminution of particles [2, 3]A typical HPGR consists of a fixed and a floating rollFeed particles experience significant reduction in size and particle strength in high pressure grinding rolls (HPGR) due to strong compression This paper presents a combined experimental and numerical study of the mechanics of cement particle breakage in a labscale HPGR under different conditionsExperimental and numerical investigation of particle size and

- metal crushing machine manufacturer

- استفادة منخفضة من خام الحديد الهيماتيت

- حجر الكوارتز الأبيض الثلج

- احصل علىadvanced gold magnetic separatorالسعر

- second crushing plant sale

- الرسم البياني التصنيع تدفق عملية سحق خط

- معدات تعدين البنتونيت في مصنع التجهيز

- مطحنة الأسطوانة كسارة الصخور المحمولة

- high quality disk filter in samoa eastern

- السعري طحن يد آلة كسارة للبيع

- مصنع cruser في جهارخاند pakur

- الجبس الشاشة كسارة الأسطوانة

- ore beneficiation production line

- معدات التكسير والغربلة الحجرية التكاملية للبيع

- حول آلة كسارة محجر الحجر

- از کجا می توانم موج شکن پیدا کنم

- roller mill yemen for sale

- الكسارة لكسر الصخور في الهند

- خط سحق الحجر المستخدم

- تولید کنندگان سنگ شکن فکی در پاکستان

- scrap metal crusher in south africa

- أهمية الكاولين في الطلاء إنتاج

- مدل های سنگ شکن فکی همراه

- آلة السفع الرملي الجافة

- quarry crusher minning in nigeria

- صور محطم المعدات الأولية

- الشركات التي تزود شاشات الاهتزاز في جنوب أفريقيا

- كيفية ارساء الناقلات على عواماتلتحميل النفط

- Pe Series Small Small Size Jaw Crusher

- ماشین آلات سنگ زنی در کارخانه سیمان استفاده

- تستخدم مطحنة الكرة السيراميك في الهند

- سنگ شکن های بالاست برای فروش کنیا

- www vigivomil com ve

- نوع السودان الفك كسارة واحدة تبديل الشحوم

- القدرة تغذية كسارة الفك 30 x 48

- كسارة أورانوس الأولية

- bhilwara industrial directory

- غبار الأسمنت على أنواع فراجاريا pdf

- اسطوانة واحدة مخروط هيدروليكي تصميم كسارة النموذج

- أحدث صور النباتات كسارة الحجر

- hs code for crusher dust

- زمین مورد نیاز برای معدن آهن

- مطحنة الكرة المعدنية جبال الألب

- دراسة جدوى أعمال المحاجر

- Iron Pyrite Processing Plant Powder Grinding Plant

- مبيعات كسارات الفك مستعملة في الجزائر

- مطحنة الحجر المحمولة المستخدمة للبيع أونتاريو

- مطحنة الكرة الصين vpack

- mining menral northumberland

- محجر الكوارتز السيليكا

- أعمال تعدين الحجر في مصر

- كاثي فيليبس آلة كسارة خام الذهب

- mobile crusher pelopor

- کارخانه طلا کارخانه طلا برای فروش در آفریقا

- شراء الفك محطم سعر $

- پانسمان مواد معدنی به تصویب رسید

- the discovery of gold mines in south africa

- مطحنة كونتوه جامبار

- كسارة الجرانيت علي بابا الصين لمستثمري التعدين

- المطاحن الصغيرة للبيع إيطاليا

- Granite processing latest

- مصنع شفط الغبار لكسارات الصدم

- عملية تصنيع الاصطناعية آلة صنع الرمل

- فلم سيدات من الربيع كسارات

- Tooth Roll Crusher For Coal Mine And Coal Preparation Plant

- كيف يتم طحن جعلت الحجر

- فوائد للتنقيب المنغنيز

- j65 دليل صيانة كسارة مخروطية

- TON chemicals instrumentals p ltd

- الشركة المصنعة للكسارة المتنقلة والغربال

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت