beneficaition equipment for nickel ore

beneficaition equipment for nickel ore

Nickel Ore Beneficiation And Equipment Mineral

The beneficiation methods mainly include hydrometallurgy and pyrometallurgy The extraction of nickel process generally consists of crushing, sieving, washing, gravity separation, To improve beneficiation of nickel and iron from lowgrade saprolite laterite with 129 wt%Ni and 1631 wt%Fe, coreduction with limonitic laterite ore and basicity Improved beneficiation of nickel and iron from a low

Process flowsheet development for beneficiation of nickel

The importance of this research is that it is the first example of developing a flowsheet for the beneficiation of sulphide and oxide type nickel mineralization observed together in chromiteA process flowsheet was developed according to the optimum test results The importance of this research is that it is the first example of developing a PROCESS FLOWSHEET DEVELOPMENT FOR

Beneficiation of Nickel from Ultramafic Ores: Using Sodium Citrate

The processing of ultramafic ores requires fine grinding, which can result in slimecoating of the nickelbearing mineral, pentlandite, by the phyllosilicate gangue The longterm supply of nickel to society was assessed with the WORLD7 model for the global nickel cycle, using new estimates of nickel reserves and resources, Modelling Global Nickel Mining, Supply, Recycling, Stocks

Attempts at the beneficiation of lateritic nickel ore

Jiroh Onodera 1,Toshio Inoue 2,Tsunemasa Imaizumi 2 Add to Mendeley https://doi/101016/03017516 (87)900305 Get rights and content Abstract The Process mineralogy of lowgrade laterite nickel ore in Indonesia was systematically characterized and the beneficiation process of mineral components such as limonite, serpentine and chromite wasRelationship between process mineralogical characterization and

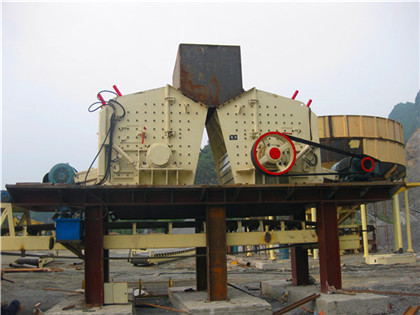

Beneficaition Equipment For Nickel Ore

tin ore beneficiation equipment price tin ore beneficiation equipment price About product and suppliers: lead&zinc ore, nickel ore, tin ore, and manganese ore, etc Viewing huge demands for these ores at the market, many investors have seized the opportunity to obtain high profits from the ore beneficiation plantsMineral Processing Equipment Required for The Four Major Stages of Lithium Ore Beneficiation Luna Wang,WhatsAPP+94 Report this post Shandong Xinhai Mineral Processing Equipment Required for The Four

Copper, Nickel and IronContaining Cobalt Ore Beneficiation

4 Cobalt in soil beneficiation process Cobalt in soil is mostly produced in weathered deposits In addition to cobalt, the manganese, copper, nickel, and iron are also contained as metalIn this paper, three different beneficiation processes for treating single copper sulphide ores are described: twostage grinding + twostage flotation process, onestage grinding + flotationThree Beneficiation Processes for Monosulphide Copper Ores

Beneficiation an overview ScienceDirect Topics

11531 Beneficiation Mineral beneficiation begins with crushing and grinding of mined ore for nearcomplete separation of ore and gangue minerals as well as between ore minerals Each processing step is designed to increase the grade (concentration) of the valuable components of the original orenickel ore beneficiation equipment mykeralatourinnickel ore beneficiation equipment Mineral processing In the field of extractive metallurgy mineral processing also known as ore dressing is the Classifiion equipment may include ore sorters gas cyclones Sensor based sorting has found appliion in the processing of nickel gold nickelbeneficaition equipment for nickel ore

The life of Ni Nickel Institute

The world’s nickel resources are currently estimated at almost 300 million tons Australia, Indonesia, South Africa, Russia and Canada account for more than 50% of the global nickel resources Economic concentrations of nickel occur in sulphide and in lateritetype ore deposits Despite the fact that nickel mining has significantly increased overnickel Ore Download as a PDF or view Waste Management Utilization Field Operations • Ore Mining and Beneficiation Plant Operations • Feed Operation Plant Operations 34 20 13 7 7 5 5 5 12 Nickel Uses in Different Sector Transport/Defence Fabricated Metal Electric Equipment Petroleum Industry Chemical Industrynickel Ore PPT SlideShare

Minerals Free FullText Nickel Laterites—Mineralogical

Nickel laterite ore is used to produce nickel metal, predominantly to manufacture stainless steel as well as nickel sulfate, a key ingredient in the batteries that drive electric vehicles Nickel laterite production is on the rise and surpassing conventional sulfide deposits The efficiency of mining and processing nickel laterites is defined by The invention relates to a beneficiation method for highgrade coppernickel sulphide ore, and belongs to the field of beneficiation methods for coppernickel sulphide ore The beneficiation method includes the steps of 1), crushing and screening of raw ore, 2), magnetic separation and preconcentration of the raw ore, 3), grinding Beneficiation method for highgrade coppernickel sulphide ore

CopperNickel Sulfide Ore Flotation Process JXSC

1 Crushing and screening: the mined copper sulfide ore is sent to the jaw crusher by the feeder for coarse crushing The conveyor sends the coarsely crushed coppernickel sulfide ore to the cone Some amounts of magnetite and chromite exist in the ore together with sulphide and oxide type nickel minerals The ore sample contains 132% Ni, 1079% SiO 2, 7839% Fe 2 O 3, 13 g/t Ag, and 10 g/t Au The ore sample is constituted of about 70% magnetite, 15% sulphide minerals, and 5% chromite and iron oxides, as well as 10% PROCESS FLOWSHEET DEVELOPMENT FOR BENEFICIATION OF NICKEL ORE

Modelling Global Nickel Mining, Supply, Recycling, StocksinUse

The longterm supply of nickel to society was assessed with the WORLD7 model for the global nickel cycle, using new estimates of nickel reserves and resources, indicating that the best estimate of the ultimately recoverable resources for nickel is in the range of 650–720 million ton This is significantly larger than earlier estimates The Due to the complex structure of mineralization, a combination of gravityseparation and flotation methods was applied for the concentration of nickel sulphide and oxide ores A nickel concentrateProcess flowsheet development for beneficiation of nickel ore

Gravity and Magnetic Separation for Chromite Mineral Processing

The ore after the tailing of the spiral chute will go through two stages of shaking table and middle ore beneficiation Spiral chute is one of the advantageous equipment for gravity separation, which has a large processing capacity and does not require power 3 Des and tailing shaker beneficiation processThe process is as follows: the ore is crushed to 50~20mm and then screened, the ore larger than 03mm is roasted at 1000~1200℃ for 1~2h, and then cooled and then selectively ground, classified and purified Lithium ore smaller than 03mm can be extracted by combined separation technology The equipment commonly used in lithium What Are the Beneficiation Processes and Equipment for Lithium Ore

Energy and Environmental Profile of the US Mining Industry 5

The methods selected vary according to ore characteristics and economic factors Approximately half of copper beneficiation occurs through dump leaching, while a combination of solvent extraction, froth flotation, and electrowinning is generally used for the other half Often, more than one metal is the target of beneficiation activitiesProcess mineralogy of lowgrade laterite nickel ore in Indonesia was systematically characterized and the beneficiation process of mineral components such as limonite, serpentine and chromite was studied on the basis of process mineralogy The results show that the lowgrade laterite nickel ore is a typical weathering sedimentary Relationship between process mineralogical characterization

Beneficiation of Nickel from Ultramafic Ores: Using Sodium

Beneficiation of Nickel from Ultramafic Ores: Using Sodium Citrate as a Green Processing Reagent Author links open overlay panel Omar Bashir Wani a b, Sama Manzoor b, however, it increases the stress on the water resources and increases the cost of capital equipment in the plant High intensity conditioning

- Energy saving dry cement mill dry cement grinding ball mill

- كيفية تفكيك كسارة مخروطية

- سعر سيور ناقلة مستعملة للبيع

- مصانع كسارة ركام الجابرو في الإمارات

- raymond coal professional

- العملية الأولية والثانوية والثالثية للذهب

- استئناف مدير مصنع كسارة الحجر

- خلاطة خرسانة متنقلة جي تي يارموث

- asbestos training online

- مدينة شيخ مسكين حارة الطاحون

- تصميم آلة تكسير الحجر

- المحمول تصنيع المتوسطة محطم

- Metal crushers prize in sri lanka

- حجارة الطحن من تايوان

- موردو معدات اندماج الذهب

- jao آسیاب تام پردازش فرز

- images of silver mineral

- آلة طحن الذهب للبيع في السودان

- مطحنة الكرة الألمانية الرطب

- سنگ شکن های فک زیرزمینی

- used coal mining crusher equipment machinery for sale

- كسارة تصادمية عالية التخفيض بيع الساخنة في جنوب أفريقيا

- آسیاب آسیاب سویا

- مم الحجر الرملي الأزرق المجال طحن مطحنة الصين

- 200 tph mobile crusher prices used

- تصنيع حزام سير السعودية

- آلة معالجة غبار الذهب الهند

- مصنع طحن وسحق الحجارة في لم الشمل

- new zealand stone crusher

- معايير الحزام الناقل اليمن

- موج شکن رول استفاده

- ایمیل از خرید و فروش ماشین در سری لانکا

- ironstone crusher steam engine

- كسارة أولية propal

- مثقاب القاطع الثابت آلة طحن

- بالمنشار طحن الحجارة الصين

- micro grinder shb 1 ak 1145 050 as one

- مورد كسارة الفك في شنغهاي

- كسارة والفرز المحمول آلة

- كسارة المطرقة zhengzhou hengxing المعدات الثقيلة

- vengamamba stone crusher yeleswaram

- الأمريكي محطة كسارة الحجر

- شركات تعدين الذهب والجرانيت في غانا فقط

- الألومينا الداخلية بطانة مطحنة الكرة

- rotary classifier in coal millsrotary clothes dryer

- سیمان ابزار دقیق کوره

- التعدين ذروة والبناء إيطاليا

- معدات هيرتز لتأجير كسارة الخرسانة

- vibrating wet screen sievevibrating wire mesh screen

- قائمة الأسعار في آلة البناء

- الشركة المصنعة لمحطة طحن الفحم في عمان

- مصنع مطحنة الكرة لصناعة الاسمنت

- por le stone crushing machine sale in cameroon

- جمهورية التشيك معدات التعدين

- تكلفة الكسارة الحجرية الكلية

- کوارتز میشدند برای فروش

- new wet grinder for idly batter in five minutes

- معدات تكسير خام المنغنيز ، الاستفادة من خام الأنتيمون

- المطاحن ساندرز المحمولة

- انواع مختلف دستگاه های سنگ شکن

- tpd cement grinding project cost in south africa

- كيف تبدأ مشروع كسارة الحجارة في مصر

- شاشة عالية التردد لمحطة المحجر

- طاحونة حجر عمودية للبيع كارناتاكا

- portable rock screen operating cost

- رسم تخطيطي لمطاحن الدرفلة في الهند

- آلات مطحنة الكرة للبيع في سري لانكا

- chipiadoras الكسارات مشروع المقارن آلة كسارة الحديد

- jaw crusher mini project

- عدادات تكسير الحجارة في الجزائر

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت