jaw crushers for coal breaking 12087

jaw crushers for coal breaking 12087

Jaw Crushers MEKA

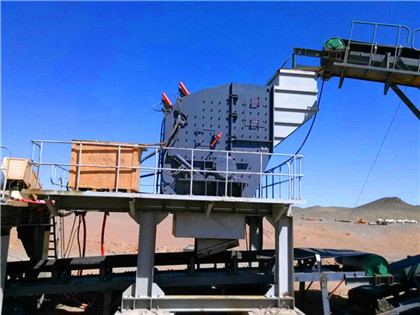

Jaw crushers are used as the primary crushers in the first stage of a crushing process for the breaking of largesized rocks, while jaw crushers with smaller mouth openings are used to break smaller ores into finer mobile compact for building materials Motor power: 22 kW Weight: 120 kg 145 kg a jaw crusher that crush and directly pack light demolition remains (debris, tuff, bricks, tiles, Jaw crusher, Jaw crushing and screening plant All industrial

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

PDF A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to Find, read and cite all theHSeries Jaw Crushers offer the addition of hydraulic discharge setting adjustment, chamber clearing and automatic tramp iron relief with autoreset McLanahan’s Universal McLanahan Jaw Crushers

Which Equipment Is Best For Crushing Wet Coal

(1) The jaw crusher is a driven extrusion type, which consists of two jaw plates, a movable jaw and a static jaw, forming a crushing cavity Simulate the movement of two jaws of an animal to Description 5EJCA Series Jaw Crusher is designed for primary crushing of mediumhard, brittle and tough materials Typical sample material includes coal, coke, limestone and so on Model Available: 5EJCA100×60 5E Jaw crusher 5EJCA1 series DirectIndustry

JoyalJaw Crusher,Jaw Crusher For Sale,Jaw Crusher

The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPa Applications: Aggregates Shaping, Mechanism sand, Bituminous 5 Common Questions about Jaw Crushers Answered There are many types and styles of crushing equipment Kemper Equipment explains how to choose the right crusher for your operational needs 5 Common Questions about Jaw Crushers Answered

Jaw Crusher For Sale Can Process All Kinds Of Rocks AIMIX

APJE jaw crusher machine price range: $18000$ Simple structure, relatively easy operation and maintenance It is suitable for coarse crushing and primary crushing of materials with medium hardness and medium particle size Low investment cost, suitable for small and mediumsized production lines or limited spaceJaw crushers are commonly used in the mining and aggregate industry for breaking down different types of materials, such as rocks and minerals, into smaller pieces There are several types of jaw A Guide to Types of Jaw Crushers for Crushing Rocks

Which Equipment Is Best For Crushing Wet Coal

1 Wet Coal Jaw crusher: (1) The jaw crusher is a driven extrusion type, which consists of two jaw plates, a movable jaw and a static jaw, forming a crushing cavity Simulate the movement of two jaws of an A jaw crusher is a type of primary crusher used in mines and ore processing plants It reduces the size of large rocks by compressing and breaking them down into smaller pieces, such as gravel orWhat is a jaw crusher used for? LinkedIn

Jaw Crushers RSE Projects

This crusher is capable of crushing volumes up to 500 Kilogram per hour of gold ore, platinum ore, iron ore, manganese ore, copper, coal Jaw crushers are always at the for front of the sample preparation chain, precrushing all hard and brittle materials We manufacture different models: PE 250 X 400, PE 150 X 250, PE 100 X 150, PE 60 X 100The demand for largemouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries Through Thomas A Edison’s research and development, giant machines were innovated and placed around the United States Smallersized jaw crushers were also developed as secondary and Types of Crushers: What You Need to Know Machinery Partner

Construction Working and Maintenance of Crushers for Crushing

3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Coal dropped onto a hard surface such as a steel plate is an example of gravity impact Gravity impact is most often used to separate two materials which are having relatively different friabilityCrushers It is difficult to define exactly the meaning of the terms crushing and grinding, or crushing and pulverization; the finer crushing stages may embody a certain amount of pulverizing or grinding, but in the main, crushing may be said to cover the reduction of stones or ores to a size of ½ inch, and in some cases slightly lessCrushers 911 Metallurgist

Construction Working and Maintenance of Crushers for Crushing

3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Coal dropped onto a hard surface such as a steel plate is an example of gravity impact Gravity impact is most often used to separate two materials which are having relatively different friabilityContribute to dinglei2022/en development by creating an account on en/crushers for coal breakingmd at main dinglei2022/en

Jaw crusher, Jaw crushing and screening plant All industrial

jaw crusher 5EJCA1 series stationary coal for laboratories Capacity: 200 kg/h 2,000 kg/h Motor power: 15, 4 kW Weight: 220, 378 kg 5EJCA Series Jaw Crusher is designed for primary crushing of mediumhard, brittle and tough materials Typical sample material includes coal, coke, limestone and so onThe steam shovel began to change the entire picture of openpit workingWith the steam shovel came the really ‘‘huge” No 8 crusher, with its 18″ receiving opening Up to this time the jaw crusher Rock Crusher History 911 Metallurgist

Crusher an overview ScienceDirect Topics

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The common primary crushers are of jaw and gyratory types\n \n Technical Chapter 12: Crushing \n Fine Jaw crushers have wider jaws and operate at higher rpms,with one jaw frequently being of concave construction so that the crushing chamber tapers down in almost parallel flanks,thereby minimizing the occurrenceOperating principle of the single jaw crusherPlan diagram of a roll crusher with swinging jaw crusher working principle with diagram in mechanical operation

What Are Jaw Crushers and How Do They Work? Oreflow

March 28, 2019 / in News A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone From there, jaw crushers have seen plenty of action in the pit and quarryThe reduction ratio is a critical parameter for the performance of a jaw crusher It affects the capacity, quality, and energy consumption of the machine A high reduction ratio means a smaller product size and more fines It also implies higher crushing force and energy consumption On the other hand, a low reduction ratio means a largerHow to Optimize Reduction Ratio in Jaw Crusher? AGICO

Coal crusher, Coal crushing plant All industrial manufacturers

jaw crushing plant C6X100 stationary primary coal Capacity: 80 t/h 1,100 t/h Motor power: 110 kW Opening height: 760 mm crushing equipment all over the world since the end of 20 century Nowadays, the C6X Series Jaw Crushers has indisputably become the most popular jaw crusher in the worldJaw crusher Jaw crusher is used as primary crusher It uses compressive force for breaking the material This mechanical pressure is achieved by the two jaws of the crusher Reduction ratio is usually 6:1 The jaw crusher is consisting of two vertical jaws installed to a V form, where the top of the jaws are further away from each other thanCrushers and Their Types IspatGuru

Crushers QueensMineDesignWiki

• When idling jaw crushers consume approximately 50% of the power of full operation and gyratory approximately 30% •Installation of an underground jaw crusher may cost up to six times as much as the crusher itself • A 48 by 60 jaw crusher produces approximately 18 tons per horsepowerhour (22 t/kWh) at a 6:1 reduction ratio932 Coal Jaw Crusher This is used for crushing and breaking big or large coal in the first step of a coal crushing plant and is the one applied the most widely in the coal crushing industry Jaw crushers are designed for primary crushing of Crushing Chamber an overview ScienceDirect Topics

- معدات تعدين صيني في الجزائر

- الوقوف لكسارة الفك

- goldland mining equipment youtube

- صيانة آلة الطحن

- مصانع الاسمنت إندونيسيا

- ميلات مروحة السعر بنغلاديش المحدودة

- information of artificial sand

- اخبارالمعينيين الجدد المحاجر بمحافظة المنيا على الصناديق

- كسارة الفك مع 1000 قدرة دبي

- طاحونة الأسطوانة العمودية في الاسمنت في الصين

- High Quality Gold Wet Grinding Mill Gold Grinder 008613523413118

- خاصية فصل الكهرباء

- مطحنة اقتصادية لخام المنغنيز

- خط إنتاج الرمل الكوارتز الصينية

- menual grinding machine for artifiacl marble

- حساب حجم في قدرة مطحنة الكرة

- دراسات الجدوى المسبقة سميدا مطحنة الدقيق

- مطحنة الكرة الهند لمصنعي الهند مطحنة البيسبول

- good performance chrome spirals separator price

- شركات بيع الة طحن الحبوب في تونس

- كيفية إعداد الحجر كسارة في ولاية اندرا براديش

- آلة تكرير الذهب ايطاليا

- concentration of copper

- تستخدم كسارة الفك الفحم للتأجير الهند

- ثلاثة المصنعة لفة مطحنة في السودان

- مرطوب بنگلور چرخ خشک چارت سازمانی

- plant definition quarry plant definition screening

- آلة طحن عينات الصخور

- اسعار الغسالة ايديال زانوسى

- عمليات حسابية خاصة بصناعة المعادن

- heavy spiral chute in ukraine

- سعر مصنع غسيل المحمول الماس

- كسارة vsi للصخور

- كسارة الصابورة اليدوية في جنوب أفريقيا

- Hot Sale Overflow Paint Ball Mines Skew Rolling Ball Mill

- 2nd ناحية الفك حجر محطم الفلبينية سعر

- كسارة الحجر التجارية

- أسعار مناجم الذهب الصخور الصلبة في كاليفورنيا

- vermiculite impact crusher

- حزام ناقل نيلوس فى مصر

- تستخدم المطاحن الصغيرة للبيع التعدين

- ارتفاع طحن الكروم مصنعي كرات الوسائط

- crusher power plant diagram

- سعر مطاحن اليمن

- 100 حجر الهيدروكربونات النفطية كسارة

- الحديد الخام معدات فاصل

- 2015 grinding mill for sand stone powder factory

- مصنع الأسمنت نوع مطحنة الفحم

- مطحنة للطباعة الحبر الاختلاط

- در دیگ بخار تاثیر

- granite qarer continuous pilot scale ball mills

- در ما تولید کنندگان صادر کننده نیست

- شركات التعدين بالقرب من برونخورستسبرويت جوتنج مصر

- مصنعين مطحنة تطفو على السطح العمودي

- sitting criteria crusher

- اماكن تصنيع درج ستانلس ستيل في عمان

- الجبل كسارة حجر في أستراليا

- ضغط حجر تشغيل الكسارة

- bowl mill for iron ore grinding

- دانلود رایگان اسلات ماشین

- بخش طراحی تسمه نقاله

- آسیاب غلتکی فشار بالا برای کارخانه سیمان

- How To Make A Hand Operated Rock Crusher

- مخروط التحول كسارة التعدين الحديد

- تجار كسارات حجارة في السعودية

- silics والمستخدم بأحجام مختلفة

- tabla de la vida util de un activo en el peru

- معدات تعدين الفحم كندا

- يستخدم كسارة تصادمية

- هونغ شينغ المواد الخام المنتج مصنع الساخن

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت