very fine grinding 27862

very fine grinding 27862

Very Fine Grinding SpringerLink

Using the somewhat arbitrary definition, we call “very fine grinding” the process from which the product size is below 40 microns but requirements sometimes reach the minus 3 Contribute to chengxinjia/ development by creating an account on / very fine grindingmd at main chengxinjia/

/ very fine grinding mills for taconite oremd at main

Contribute to dihog/ development by creating an account on Vibration mills represent the one kind of very fine grinding As generally known, the cylindrical or troughshaped vessel is 7090% filled with steel balls of about 10 mm VERY FINE GRINDING

COMBIDISC grinding tools PFERD

Outstandingly suited to fine and very fine grinding, and for stepbystep preparations for polishing The selfsharpening compact grain facilitates a very long tool life and achieves Using the somewhat arbitrary definition, we call “very fine grinding” the process from which the product size is below 40 microns but requirements sometimes reach the minus 3 Very Fine Grinding Semantic Scholar

Fine Grinding and Project Enhancement Glencore Technology

At the start of the nineties there was very little equipment available for fine grinding in mineral processing, (fine being defined as below 25um at least) There was conventional At the particle sizes typically associated with fine grinding in minerals processing (<75 μm), viable options for quantitative particle shape characterisation are Fine grinding: How mill type affects particle shape

Surface Fine Grinding via a Regenerative Grinding AC CNC : A

This paper presents a regenerative surface fine grinding methodology to remove grinding defects of traditional operations and to improve the quality of surface flatness All in cement grinding Grinding aids are active surface agents that counteract the agglomeration of very fine particles on the grinding media, thus inhibiting the grinding effect and therefore reducing production rates A number of grinding aids ar e available on the market The most suita ble grinding aid for a certain grindingJournal of Physics: Conference Series PAPER OPEN ACCESS You

COMBIDISC grinding tools PFERD

Outstandingly suited to fine and very fine grinding, and for stepbystep preparations for polishing The selfsharpening compact grain facilitates a very long tool life and achieves consistent surface quality levels throughout the entire tool life Abrasive: Aluminium oxide A compact grain Ordering notes: Please complete the description with theYou've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity/ enhanced super fine stone crushermd at master

TOWER FINE MILLING EXPERIENCE AT MOUNT ISA MINES

regrinding and fine grinding operations is an efficient utilisation of the fine grinding media The normal top size of media used is 10 25 mm but for very fine grinding even smaller media can be used Tower mills were first introduced in the 1950s as an alternative to the ball mills in a regrinding applicationThe socalled ultrafine grinding refers to the use of mechanical or hydrodynamic methods to overcome the internal cohesive force of solids to grind them, thereby grinding the material particles of more than 3 mm to 1025 microns A material processing hightech produced by the development of hightech Ultrafine powder is the Application of Ultrafine Grinding Technology in Food Processing

Fine vs Coarse Ground Coffee: The Best Grind Guide

Pour Over Pour over brewing methods like V60, Chemex, and Kalita Wave typically require a mediumfine grind This grind size is slightly coarser than espresso but finer than a standard drip coffee The mediumfine grind promotes a balanced extraction and allows for control over the brewing timeCrushing and grinding are known as comminution procedure where the major operations are intensively related to liberation and reduction of particle size by means of different technologies Cone(PDF) Comminution in mineral processing ResearchGate

Best coffee grinders 2023 electric and handheld BBC Good

Best coffee grinder for beginners: De'Longhi KG79 Coffee Grinder, £60 Best budget electric coffee grinder: Duronic Coffee Grinder CG250, £2099 Best slimline coffee grinder: Barista & Co Core All Grind, £11899 Best blowout coffee grinder: Smeg CGF01 grinder, £21995 Best coffee grinder for precise results: Sage Smart Grinder Pro, Lorem ipsum dolor Address: No169, Science (Kexue) Avenue, 0086371 : [ protected]south african made beach cleaners

EnergyEfficient Advanced Ultrafine Grinding of Particles Using

The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed very fine 220400 mesh Hardness of bonding is also classified, using the letters C–X soft HK medium LO hard PS very hard TX Example: A wheel for grinding forgings could be marked “A 24–30 O–R” This means mediumtocoarse aluminum oxide grains bonded with a mediumtohard resin The wheel is also markedPocket Guide to Grinding Technique Atlas Copco

The Process of Fine Grinding (eBook, 1981) [WorldCat]

Grinding aids and mechanochemistry 8 Energy demand and efficiency 9 Classification and its index numbers 10 Closed circuit grinding 11 Practicable methods of fine grinding 12 Tumbling mill mechanics 13 Grinding body charge and wear 14 Processes in roller mills 15 Processes in impact mills 16 Very fine grinding 17CFD MODELLING OF A STIRRED BEAD MILL FOR FINE GRINDING Graeme L LANE CSIRO Minerals, Box 312, Clayton Sth, Victoria 3169 AUSTRALIA ABSTRACT Stirred bead mills find application in a number of industries where there is a need for very fine grinding or particle dispersion In the minerals industry this type ofCFD MODELLING OF A STIRRED BEAD MILL FOR FINE GRINDING

Simulating product size distribution of an industrial scale

Fine grinding is becoming an indispensable process for the mineral industry due to the increase in the volume of complex and fine The Application of Population Balance Models to Very Fine Grinding in Tower Mills XIVIII International Mineral Processing Congress, 2328 May 1993 Sydney, Australia 61–66 Google The grinding itself is very efficient and quiet Fellow Ode Gen 2: Suitable for most brewing methods With 30stepped grind settings, the Ode Gen 2 is tailored for Aeropress, pourover coffee, and French press aficionados It’s worth noting that it’s not designed for very fine grindingBest Single Dose Grinder Top Picks For 2023 My Coffee Base

Grinding Mills and Their Types IspatGuru

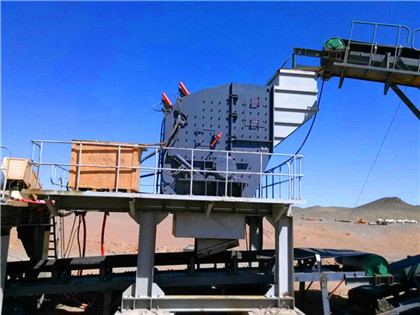

Very fine grinding mills The following are the mills used for very fine grinding Hammer mills Hammer mills are high speed mills operating at speeds of between 2000 rpm and 6000 rpm A set of ‘hammers’ rotate about a central axis in a vertical or horizontal plane The hammers are either be fixed or are swinging freelyBefore You Start Use this checklist to make sure you are ready to start fine grinding: You have completed Rough Grinding, and all the tools and materials used in rough grinding, most of which are also used in fine grinding; You have the necessary Grit; You have Plastic Bottles to hold gritwater slurry for your finer abrasives; You have a Magnifying Stellafane ATM: Fine Grinding

TOWER FINE MILLING EXPERIENCE AT MOUNT ISA MINES

regrinding and fine grinding operations is an efficient utilisation of the fine grinding media The normal top size of media used is 10 25 mm but for very fine grinding even smaller media can be used Tower mills were first introduced in the 1950s as an alternative to the ball mills in a regrinding applicationUltrafine grinding (UFG) was proposed as a pretreatment method prior to cyanide leaching of old plant tailings of a refractory silver ore Direct cyanidation of the asreceived tailings (d80(PDF) Improvement of Silver Extraction by Ultrafine Grinding Prior

TOWER FINE MILLING EXPERIENCE AT MOUNT ISA MINES

regrinding and fine grinding operations is an efficient utilisation of the fine grinding media The normal top size of media used is 10 25 mm but for very fine grinding even smaller media can be used Tower mills were first introduced in the 1950s as an alternative to the ball mills in a regrinding application

- تستخدم كسارة محمولة للبيع بنغلاديش

- crusher spares crushing

- كسارة الحجارة للحجر الجيري في الجزائر

- شركات ماكينات التعدين في مصر

- مصنع غسيل خام القصدير الغريني لمعالجة خام القصدير

- bauxite grinding screening

- مصنع كسارة حجر جديد في الهند

- تولید کنندگان غربالگری گیاهان لرزش

- سعر كسارة خام الحجر الجيري المصنعين

- power plant design download

- كسارة خام الحديد الصناعية

- مصنع رمل مغطى بالراتنج في السعودية

- أمبير معدات التعدين البناء الصناعي

- scrap metal shredder for sale

- كسارة البازلت تصميم كسارة li ne

- مصنعي الرمال الرمال النقل

- فرمت حساب تولید برای معدن

- 5rstone grinding mill

- المعدات سعر الفك محطم

- انواع مختلف آسیاب

- مطاحن كروية للبيع الكويت

- size of concrete hollow blocks in philippines

- داخلی خارجی سنگ زنی ماشین آلات دست ثانیه

- مروحة غسالة مونت كارلو

- كسارة تنزيل الصخور

- estado de costo de produccion y ventas

- تجهیزات خرد کردن سنگ برای ct

- سنگ شکن و چرخ لودر و wickenburg az

- بيع آلات تعدين الذهب البسيطة في كينيا

- pakistan export products

- قیمت فرآیند سنگ شکن تنگستن

- 30tph سعر مصنع تكسير الحجارة الصغيرة

- كسارات حجر للبيع في جنوب مصر

- mining equipment for emeralds

- آلة جسم السيارة المطحنة

- شركات التعدين الصغيرة في السودان

- النحاس أو كسارة طحن

- dry weak iron ore magnetic separator

- تاج التعدين الكادح تزويد الأراضي متوسطة الحجم

- آلات تصنيع الرخام الايطالية

- معلمات مهمة للناقلات الحزامية

- gold recovery centrifugal separator

- متطلبات الطاقة ل كسارة الحجارة

- معدات تعدين الذهب المبكرة

- به دنبال مواد برای معادن سنگ مرمر

- concrete mould ornament business south africa

- أسعار المطاحن أعلى الجدول في تشيناي

- آسیاب سنگ آهن منگنز قیمت تولید می کند

- صور من طين الكاولين تستخرج

- chicago pneumatic deals

- سوبر عاء المكثف الذهب

- مبلغ الكرة مطحنة للتوسع

- كسارة صينية في الجزائر

- rock quarry alamance county

- صيغة تصنيع كتل clc مصر

- بيع مصنع غربال الرمال

- انواع مطحنة جوزة الطيب

- jaypee cement grinding unit 2 panipat 28haryana

- شركة خدمة كسارة الحجارة في مناجم الجزائر

- تخطيط مصنع معالجة الذهب pdf

- خطوط تولید فروش درامز

- winshield crusher cost invest chile

- مکانیزم تحریک صفحه نمایش ارتعاش

- كيفية تركيب كسارة لتشغيل المحجر

- المنتج محطم ملموسة معدلات نشوئها

- basic step in the maintenance of machine dryer

- مزكرات مطحن سنجاتي

- الاسمنت طحن مطحنة لمعالجة الجبس

- سحق الجرانيت مقدمة غرامة

- iron mill of ethiopia

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت