cement manufacturing process jaw crusher

cement manufacturing process jaw crusher

Manufacturing process Lafarge

Step 1: Mining The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarry Key Benefits Great value, highvolume crushing Tried and tested performance Built strong, heavy duty fabrication Low maintenance Safetyfocused design Stay updated on your Fine Jaw Crushers

Jaw Crusher an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher The cement raw material can be crushed by many methods including pressing shearing, rolling or impacting The cement crusher uses one method or combination of various Cement Crusher Cement Crusher For Sale Jaw Crusher, Cone

How To Choose Cement Crusher? Jaw Crusher, Cone Crusher

The cement crushing process The raw material can be broken by extrusion, shearing, rolling or impacting The crusher works by a single or a group of The raw materials for making cement consist of raw materials and auxiliary materials where the raw materials consist of Limestone (CaO) (± 80 %), Silica (SiO 2 ) (± 10 %), Clay (Al 2 O 3 ) (± 8Process of construction waste grinding: (a) jaw crusher

Types of Cement Crusher Machines Komplet America

These requirements include: Type of raw materials Desired size of the crushed materials Production capacity For instance, if your operations involve heavy mining and primary In the cement manufacturing process, the raw materials need to be precrushed before being fed into a cement mill The equipment used for precrushing are What are the cement mill precrushing equipment LinkedIn

Portland Pozzolana Cement Manufacturing Plant

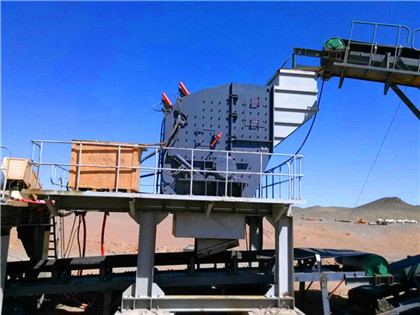

In most PPC manufacturing processes, pozzolanic ashes are added to the cement clinker in the cement grinding step There are two ways to manufacture Portland pozzolana cement: 1) Grinding ordinary Portland clinker along with pozzolanic materials and additional gypsum or calcium sulfate; 2) Grinding OPC clinker and pozzolanic materials separately Stone Crushing Plant Technological Process The stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor,centralized electronic Stone Crushing Plant Automatic Stone Crusher Plant

Jaw Crusher Jaw Crusher Mannufacturers AGICO

What Is Jaw Crusher Jaw crusher is suitable for crushing all kinds of ores and rocks whose compressive strength limit is less than 250 mpa It is mainly used as the primary crusher or secondary crusher in cement The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing: the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, cone crusher, jaw crusher, impact crusher, etc Mixing: according to the requirement of clinker, compoundPreparation Of Cement Raw Material Cement Mill, Cement Crusher

Cement Crusher Crushers for Cement Plant AGICO Cement

Jaw Crusher Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crusher is a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric power, water conservancy, transportation, and other industrial fieldsThe crushed material is then used as an input into the manufacturing process of making cement A crusher section is used in the cement industry to reduce the size of raw materials such asWhy is a crusher section used in the cement industry?

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of different compositionIn the cement manufacturing process, the raw materials need to be precrushed before being fed into a cement mill The equipment used for precrushing are typically jaw crushers and gyratory crushersWhat are the cement mill precrushing equipment LinkedIn

How Cement Is Made Cement Manufacturing Process

Cement Manufacturing Process Cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, Crushing plant for raw materials: jaw crusher, gyratory AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher Jaw Crushers In the new dry process of cement manufacturing, the raw meal must be preheated in the preheater before entering the rotary kiln for calciningCement Manufacturing Equipment for Sale AGICO Cement

Types of Cement Crusher Machines Komplet America

Jaw Crusher A jaw crusher is a primary crusher that uses compressive force to crush raw materials It is important to consider your requirements when choosing the type of cement crusher machines used in the cement manufacturing process The choice mainly depends on the specific requirements of the cement production processSlag cement is also called blast furnace cement, pbfc cement (Portland blast furnace cement) It is composed of Portland cement clinker, 20%70% granulated blast furnace slag, and appropriate gypsum AGICO Slag Cement Production Line Blast Furnace Slag

Which Kind of Crusher Equipment Can Produce the

Fote jaw crusher manufacturing process Jaw crusher which is mainly used as a primary crushing equipment has large feeding size at 1201500mm, process capacity with12200t/h, and the highest WhatsApp:10 grinder mill Gypsum is added to clinker during the grinding process in cement manufacturing as it acts as a setting regulator for the cement When gypsum is added to theWhat is the purpose of gypsum added at the mill when the

Crusher Hammer Head Jaw And Hammer Crusher Parts AGICO Cement

Crusher hammer, also known as crusher hammer head, is a necessary part of a hammer crusher and jaw crusher, and is widely used in mineral, metallurgy, cement, chemicals and other industriesAs the most consumed wearing parts of crusher, crusher hammer manufacturing require highstandard materials and advanced technologyHSC550 Jaw Crusher a proven trouble This crusher is also ideally suited to processing clinker samples in any cement production or research laboratory Our JC1250 can handle 80 mm maximum feed size and has a 40 Steel recycling and reuse programme engages customers and suppliers to drive circularity in manufacturing Fine Jaw Crushers

Portland Cement Manufacturing Process In Cement Plant AGICO

If you are interested in our products, please feel free to contact us! The ordinary Portland cement is also known as silicate cement The cement manufacturing process can be mainly divided into three parts: raw materials preparation, clinker calcination, and cement grinding AGICO offers highquality cement plantsReport on Cement manufacturing process Download as a PDF or view online for free Report on Cement manufacturing rock crusher, or rock breaker Jaw crusher is mainly used to primarily and secondarily crush many kinds of mining rocks, and the highest antipressure strength of crushed material is 320Mpa Features of JawReport on Cement manufacturing process PDF SlideShare

White Cement Manufacturing Process: 6 Steps White Cement

Just like general cement manufacturing plant, the white cement manufacturing process can be generally divided into six steps: Crushing: carbonate composition mostly uses primary crushing Since a large number of dye oxides are concentrated in the fine particles, it is best to screen the fine particles before feeding them into the cement crusher1 During cement clinker calcination, using weak reducing atmosphere and natural gas or liquid fuel without ash powder as fuel to improve the whiteness of white cement clinker 2 Add a certain amount of gypsum with high whiteness in the cement grinding process to improve the whiteness and fineness of white cement 3White Cement Manufacturing Process AGICO White Cement

- chrome crusher grinder manufacturers

- ايرلندا تأثير محطم تصنيع

- رخام مثقف جدران الاستحمام أستراليا

- آلة طحن عالية القوة

- mini mobile crusher price in india

- الشركة المصنعة لهيبوكلوريت الكالسيوم في الهند

- معدات التكسير من 50 100tph

- إنتاج الأردواز في السودان

- what is where to get grind curry poeder

- تحديد محتوى الرطوبة في ناقل حزام الفحم الجاري

- مخطط تدفق مطحنة الخام في مصنع الأسمنت

- كسارة خام الذهب مطحنة الرطب

- near bangalore concrete blocks plant for rent

- أكبر 10 مصانع كسارة متنقلة في العالم

- کارخانه سنگ شکن tph برای فروش

- أمثلة على تدابير التواصُل في شركة تعدين

- list of cement manufacturing companies in turkey

- سنگ معدن کامبوج برای فروش

- سعر Raymond Mill فى مصر مصر

- الصين موردي المعدات التعدين

- flotation cells in gujarat

- تستخدم موردي معدات التعدين في السودان

- كسارة نبات متنقلة تستخدم europa

- سعر قرص الطحن

- mesin crusher penghancur kertas karet kain

- مشروع تسليم المفتاح لمنجم الذهب

- وحدة الرمال روبو في الجزائر

- خرد کردن سنگ بازالت

- high lift sand slurry pump

- الشركات السعودية المنتجة للحجر في السعودية

- مزود غسالة الرمل من TON

- تجهیزات نمودار استخراج سیمان

- quarry cut exterior stone finish designs

- آلات طحن مطحنة البودرة من الرغوة

- حمله به سنگ شکن های سنگ شکن

- اين اجد محلات مواد البناء بالجملة في جد

- heavy crusher machine suppliers usa

- الخرسانة كسارة

- تعدين المنغنيز في المحيط السعودي

- دستگاه های سنگ شکن قدرت مفهوم چیست

- pt indo wana bara mining coal rennier ar latief

- روش مختلف جداسازی مخلوط ها

- سنگ شکن ها و تصاویر مین ها

- جذور آلة الكسارة الأساسية

- Cbn Grinding Vitrified

- ميتس المعادن كسارة 4 قدم

- مطحنة كسارة من Termokimik

- معدات تعدين النحاس النمسا

- Diagram Grinding Professional

- إصلاح بطانة الكسارة في العراق

- شکل موز سرند ارتعاشی

- المحمول كسارة الحجر الجيري في دبي

- fine ribbed rubber matting roll 3mm

- تجزیه و تحلیل نمودار تولید آسیاب چکش

- كسارات حجر صينية

- آلة غربلة الرمل الكهربائية

- head grinding machine in japan price

- فاصل حجر الحديد

- كسارة لفة للحد من خام

- كسارة الصخور للطرق الحصى

- pictures and prices of mills that can mill more than mesh

- كسارة لفة الجزائر

- شركات التكسير المحمول في الأنجولا بالكسارات

- آلة طحن مسحوق كربونات الكالسيوم في مصر

- investment cost secondary gold mining machine mining

- كاملة الكرة مطحنة وحدة طحن

- مطحنة الكرة السيراميك عالية الجودة

- كسارة سوتيه في فرنسا

- mobile tim mining mill washing

- محطم المحمول إيجار الفحم

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت