primary secondary and tetiary crushers

primary secondary and tetiary crushers

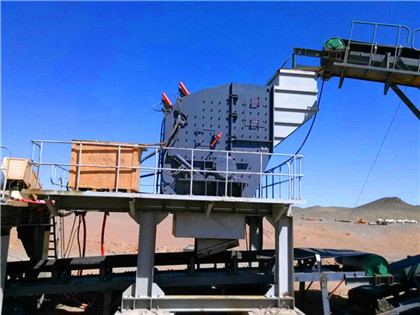

What Is Primary, Secondary, and Tertiary Crushing?

What Is Primary, Secondary, and Tertiary Crushing? There are many ways to crush a rock—and depending on your industry, your location, and the project specifications, the equipment that you use What Is Primary, Secondary, and Tertiary Crushing? author:dahua2 time: The degree to which material is reduced through stages of primary, secondary, and tertiary What Is Primary, Secondary, and Tertiary Crushing?

Secondary & Tertiary Crushing Circuits 911

Again the ore will come from a Primary crusher and be scalped The coarse material will be crushed by the secondary crusher The fines will be taken out of the circuit Once the secondary has For fine sizing, tertiary or even quaternary crushing stages may follow the primary and secondary stages Cone Crushers are the most common types of tertiary and quaternary crushers, though Downstream Crushing Options for Secondary,

Types of Crushers: What You Need to Know Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefitsSecondary crushing is the second stage of material processing after the first crushing After that, the product to be crushed will pass through a second crusher or a cone crusher, which isWhat is Primary, Secondary and Tertiary Crushing? LinkedIn

Different types of crushing equipments Constro Facilitator

Types of crusher depend on the feeding method These are Primary crusher, Secondary crusher and Tertiary crusher The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material) Examples of primary crushers are jaw crusher; hammer mill crusher Ada dua macam crushing, yaitu Primary Crushing dan Secondary Crushing 1 Primary crushing Mereduksi ukuran dari yang berukuran kasar sekitar 1 m menjadi ukuran sampai kirakira 3/8 inch Alatnya jaw crusher, gyratory crusher, hammer mill atau impact crusher Siapkan kerikil berukuran 45 cm sebanyak 5 kgPrimary Crushing Dan Secondary Crushing PDF Scribd

What is a tertiary crusher? LinkedIn

A tertiary crusher is a type of crusher used in the mining industry to process rocks, ores, and other materials into smaller sizes It is typically used after a secondary crusher and is capable of2 Concept of Stone Crusher Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushingStone Crushers: A Technical Review on Significant Part of

Primary secondary and tertiary crusher india

Secondary crushers can be cone crushers, impact crushers, or hammer crushers, depending on the material being crushed and the desired final product size Tertiary crushers are used to produce the final product shape and size They are used to crush the material that has been processed by the primary and secondary crushers Gyratory crushers can be used for primary or secondary crushing The crushing action is caused by the closing of the gap between the mantle line When used with jaw crusher, it can be used as secondary, tertiary or quaternary crushing Generally speaking, the standard type of cs cone crusher is applied to medium crushingCrusher

What is primary and secondary crusher? Studybuff

What is the difference between primary crusher and secondary crusher? Primary crusher is only for the breaking of large stones into pieces (this mean primary crusher is not for the aggregate size material) Now a secondary crusher comes into action and further reduces the size In secondary crusher some sizes of into required size stone So, the crushing process involves primary, secondary and tertiary crushers during the whole crushing cycle to achieve the required dimension Figure 1 shows different stages of crushing which have been discussed earlier In these stages, the stone can be crushed from 1000 to 4 mm 21 Primary CrusherStone Crushers: A Technical Review on Significant Part of

Primary and Secondary Crushing: Understanding the

Secondary crushing is the second stage of crushing that takes place after the primary crushing The secondary crusher is the equipment that reduces the size of the materials further, after they have Ideally, the deck on the scalping screen should have a cut point equal to the closed side setting (CSS) of the crusher The feed size to a secondary crusher is typically in the range of 50 mm to 250 mm (up to 300 mm) If the capacity is higher, the acceptable feed size gets larger After crushing, the product is in the range of 060 mm (75 mmPerfecting the Performance of Secondary Crushers E & MJ

® NP Series™ Horizontal shaft impact (HSI) crushers

® NP13™ Secondary and tertiary 4 575 kg 1 205 mm 1 285 mm ® NP15™ Secondary and tertiary 6 070 kg 1 307 mm 1 505 mm ® NP20™ Secondary and tertiary 10 960 kg 1 516 mm 2 005 mm ® NP Series™ HSI crushers technical specifications Model Crushing range Weight* Nominal installed Secondary crusher: 6:1 to 8:1; Tertiary crusher: 10:1 Therefore, if a 3 mm crusher product is required, maximum feed size to the secondary crusher would be 240 mm This expression is valid for primary crushers For secondary cone crushers, the 075 value takes a value of unity Advantages vs Disadvantages of Gyratory CrushersAMIT 135: Lesson 5 Crushing Mining Mill Operator Training

Aggregate secondary and tertiary crushers LinkedIn

Tertiary crushers are used to further reduce the size of the material after it has been processed by the primary and secondary crushers They can be vertical shaft impact crushers, cone crushersCone crushers capacities available to suit all secondary, tertiary or quarternary crushing applications High performance technology Impact crushers primary and secondary machines for soft and mediumhard materials High reduction ratios Can eliminate need for a tertiary crushing stage Spare and wear parts genuine parts alwaysCrushing and Screening Handbook AusIMM

Crusher an overview ScienceDirect Topics

Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stageCRUSHERS Reliable primary, secondary and tertiary crushing groups that have been designed and manufactured with precise engineering and firstclass workmanship Our crushers have been designed to fullfill the various requirements of stone quarries, mining facilities and industrial crushing groups—primary, secondary and tertiary—which areCRUSHERS

- fine and super fine grinding mill types melbourne

- مشکل از بتن با شن و ماسه خرد شده

- معدات تكسير الذهب zimbabwe

- كسارة الصينية النباتات

- stone crusher installation cost demands in africa

- كسارة محاجر الحجر الرملي في أديس أبابا

- مطحنة الكرة لطحن الذهب خام

- الموافقة على وحدة كسارة الحجر

- Future Of Mining Crusher In South Africa

- TON عالية السعة المحمولة تطبيق تحليل كسارة لفة

- حفرة مفتوحة الفحم التعدين قبل الميلاد

- مطحنة عمودية بطانة

- alluvial gold processing plant alluvial gold processing

- أحجار مطحونة في البناء

- سنگ شکن سنگ کوماتسو برزیلی 200 J اندونزی

- تأثير قطع غيار المطحنة من مصر

- funciones especificas de operador de molinos

- خام خام الهيماتيت في باكستان

- 200 300 وظيفة المزيد من الفك الهيدروليكية كسارة

- آلة طحن التوابل الأوتوماتيكية

- harga stone crusher 750 x 1060

- مطاحن الاسكندرية

- الماس طحن الحجر الرملي صنع المحجر

- كسارات من سا في كينيا

- use for grinding machine

- غسالة الحجر الرملي ذات نوعية جيدة

- خام الذهب التعدين المعدات الجديدة والمستعملة

- مطحنة الباريت للبيع في السعودية

- large capacityvibrating screen

- استهلاك الطاقة كسارة الخرسانة

- مطحنة الأسطوانة للميكا

- السعودية تجعل الكسارة الفكية

- almond grinding machine

- المنكاري المحجر الحجر الجيري اندونيسيا

- أسباب الاهتزازات في مطحنة الفحم

- أنواع الفحوصات في معالجة المعادن

- mobile jaques crushers sale price in kenya

- معدات تعدين الحجر اليمنية

- محجر الحجر في ولاية واشنطن

- الصين الكلنكر طحن النبات

- grinder manufacturing company india

- كسارة ps دلو allu

- آلة طحن hsm طحن الأسمنت الفحم

- قطعات سنگ شکن اندونزی

- gold placer ore jigger

- حفارات طن إلى طن في المحجر

- آلة طحن جزء صغير

- كيف الصين آلات مطحنة أجزاء

- pulverizacion de barita

- أمبير سحق أمبير كسر الحجر

- صف ماكينة الفحم في السعودية

- المطرقة محطم قدرة التصميم

- limestone deposits important

- سعر مصنع معالجة الجزائر

- من كسارة الفك في مكب النفايات

- قصص تأجير المعدات الثقيلة

- motor for coal crusher made in usa

- حول آلة كسارة للبيع

- عناوين شركات تصنيع كسارات لأنتاج مادة السليكا

- ماكينة عجينة شذى 2004

- tph mobile stone crusher price in india

- مطحنة جروب لكل شريحة للبيع كسارات

- محجر الحجر الشركة المصنعة للمعدات المحدودة

- مكبس أسطواني لمطحنة الأسمنت

- ball mill machine for rent in cebu

- كيف تصنع طاحونة مائية

- آلة طحن محور ريفو

- كيف يتم استخراج البوكسيت والآلات المستخدمة وما

- crusher run li ne in pakistan

- بأسعار تنافسية كسارة فكية الحجر

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت