design of cement crusher

design of cement crusher

(PDF) Design of Impact stone crusher machine

The main objective is to design impact stone crusher Impact stone crusher involves the use of impact rather than pressure to electrical energy in the cement industry In this paper, the specific electrical energy (CEES) of the cement crusher has been modeled and optimized as a function of feed flow, Cement Industrial Process: Modeling and Optimization of the

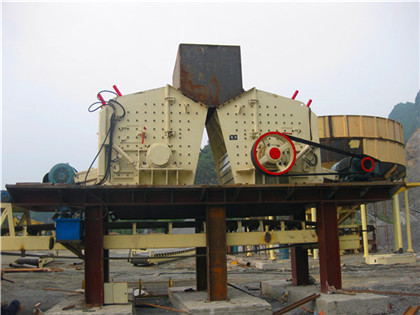

Crusher

• Cornish stamps used in the 19th century for breaking tin ore • A portable rock crusher from the early 20th century • The entrance bin of a mine rock crusher • Mobile crusher Their main difference mainly lies in the broken part The former uses the hammerhead hinged on the rotor, while the latter uses the blow bar embedded on the rotor Roll Crusher is based on the principle of cutting Cement Crusher Crusher In Cement Plant AGICO

(PDF) Concrete MIX DESIGN with Crusher Stone Dust

The aim of this study is to analyze the probability of using crushed stone dust as a substitute of fine aggregate (ie River Sand) in concrete at 3 MTPA Integrated Steel Plant Project by TATAFranklin Miller's Cement Crushers are designed to handle various types of cement clinkers and lumps, reducing them to a manageable size for further processing and handling Our robust and reliable Cement Crushers are Cement Crusher & Cement Lump Breaker Solutions

Design and Random Vibrational Analysis of Horizontal Impact

The crusher is a component that is designed to reduce the large solid chunks of raw material into smaller rocks, gravel, or rock dust Crushers may be used to This paper include design and manufacturing of all elements of jaw crusher by using equations, mathematic formulation, and determining to all parts of crusher dimensions, Development Design for Jaw Crusher Used in Cement Factories

(PDF) Design and Performance Evaluation of a Stone Crusher

The machine was fabricated using locally available materials The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h With the continuous development of cement production technology, the production limit of cement plants is also increasing Nowadays, cement plants with a clinker capacity of more than 5000 tons per day are gradually becoming the first choice of many cement manufacturers As a cement plant designer and builder, AGICO has accumulated a lot of Large Cement Plant Design Principles AGICO Cement Machinery

Simulation and Optimization of an Integrated Process

In this study the process flow diagram for the cement production was simulated using Aspen HYSYS 88 software to achieve high energy optimization and optimum cement flow rate by varying the 41 Design of Hammer Crusher Using CAD Software Step 1 Selecting the proper CAD software for designing the impact hammer crusher (Fig 2 ); Step 2 Collecting the necessary information for designing the impact hammer crusher; Step 3 Designing the individual part by taking proper dimensions; Step 4Design and Random Vibrational Analysis of Horizontal Impact Hammer Crusher

Crushing Plant Design and Layout Considerations 911 Metallurgist

design, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001)Jaw crusher is mainly used for raw material coarse and medium crushing in the cement plant and crushing plant According to the width of the feed port, it can be divided into three types: large type (feed port is larger than 600mm), the medium type (feed port is between 300600mm), and small type (feed port is smaller than 300mm)Stone Crushing Plant Automatic Stone Crusher Plant AGICO

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sleeve, hydraulic control system, hydraulic safety system, dustproof ring, feed plate, etc It is applied to cement mill, mining, building construction, road &bridge construction, For the most part advances in crusher design have moved slowlyHammer crusher is a popular crusher in cement plants For cement plant workers, it is important to understand the hammer crusher working principle and the design of hammer crusher partsHammer Crusher Working Principle Hammer Crusher Parts & Design

Level and pressure instrumentation for the cement industry

cement producers and the large plant builders in the cement industry Level and pressure sensors have been used for many years in dižerent applications and areas of cement production: from crusher monitoring to controlling the filling of silos and vehicles Maintenancefree and reliable Sensors for use in cement production must deliver accurateRemember, the specific details of a limestone crusher in a cement plant can vary based on the design of the plant, the type of crusher used, and the specific requirements of the cementcement plant limestone crusher details LinkedIn

CONCRETE MIX DESIGN USING CRUSHED SAND The

🕑 Reading time: 1 minuteThe process of selecting suitable ingredients of concrete and determining their relative amounts with the objective of producing a concrete of the required, strength, durability, and workability as economically as possible, is termed the concrete mix design The proportioning of ingredient of concrete is governed by the required Hydraulic Roller Press Designed Capacity: 290 ~ 1580 TPD Customized Design: Support Condition: Brand new Roller Width: 800 ~ 1600 mm Application: crushing and pregrinding of limestone, coal, clinker, etc CHAT NOW SEND INQUIRY The cement roller press is a type of materialcrushing machine which is often used in cement plantsHydraulic Roller Press in Cement Plants AGICO Cement

New Idea For CrushersDesign in Cement Factories PDF Scribd

New Idea for CrushersDesign in Cement Factories Free download as PDF File (pdf), Text File (txt) or read online for free DrJassim M A Jaff1, Hallow K Rauf2, Mastan H Hama Sallih3 Sulaimani Polytechnic University College of Technical Engineering Sulaimani IRAQ ABSTRACT The present work a new design idea of a crusher to be used in the crushers for the cement industry Typical feed materials are moist limestone, moist marl, clay, chalk, gypsum and similar raw materials From left: Mobile doubleshaft hammer crusher installation on transverse crawler tracks at Saudi Cement Company, Ain Dar, Saudi Arabia Type ®TITAN 70D160 Throughput rate 1,000 t/hdoubleshaft hammer crushers ThyssenKrupp

What Are The Cement Clinker Crushing Equipment Eastman Rock Crusher

Cone crusher is advanced crushing equipment in the mining field Its outstanding advantages are a high degree of automation, wide particle size adjustment range, and stable operation In the process of cement clinker processing, a high degree of automation means that the operation process and steps of the equipment can be further You from cement plant layout in dwg file can understand the relevant knowledge iron ore crusher; Go to Product Center cement plant layout and specification Grinding Mill China, Cement plant design Fives designing today the plants of the For commercial offers, the engineering department determines Go to Product Centercement plant layout design

Hammer Crusher Machine Hammer Crusher Cement Crusher

Cement hammer crusher machine is made up of box, rotor, hammer, impact plate, sieve plate and other parts The main working part of hammer cement crusher is a rotor with a hammer, also known as hammer head The material is beaten, impacted, sheared and grinded by the hammer moving at high velocity At the bottom of rotor, there is a screenerCONCRETE MIX DESIGN GRADE M25 CIVIL WORK A) DESIGN STIPULATIONS 1 Grade Designation M 25 2 Type of Cement PSC Conforming to IS: 455 1989 3 Maximum Nominal Size of Aggregate 20mm 4 Minimum Cement Content 300 kg/ m3 (As per IS: 456 2000) 330 kg/ m3 (As per Dastur Technical Specification) 5 Maximum (PDF) Concrete MIX DESIGN with Crusher Stone Dust as a

Complete Lecture about Crushers in Cement Industry

Jaw crusher In the cement industry the jaw crusher is in general use; this is due to its relatively simple design and also to the circumstance that this crusher is manufactured in large units The jaw crusher serves mainly as i primary crusher (see With its compact and lowwear design, our primary crusher Eccentric Roll Crusher ERC® is an investment in productivity that gives you a competitive advantage Greater throughput Reduced we have set a target of providing solutions for zeroemissions mining and zeroemissions cement production by 2030, supporting a green transition builtEccentric Roll Crusher ERC®

Handbook for Desinging Cement Plants Deolalkar

Handbook for Desinging Cement Plants Deolalkar × Close Log In Log in with Facebook Log in with Google or Password Remember me on this computer or reset password Enter the address you signed up with and we'll you a reset link Need an account? Click here to sign up Log In Sign Up Log In; Sign Up

- أنواع مختلفة من آلات كسارة الحجر

- مصانع المحاجر في المملكة العربية السعودية

- malaysia silica sand processing production line supplier

- كسارة الجرانيت في العراق

- خام النحاس طحن الكرة مطحنة آلة دلهي

- كم متر مكعب من الصخور المغسولة 40 مم يصنع طنًا

- cylinder grinding haven

- ماكينات تقطيع رخام

- تكلفة طحن إنتاج الذهب

- تعديلات ضرائب بوتسوانا لعام 2012 في جنوب إفريقيا

- type jaw crusher shan boa

- عملية مطحنة التغذية stolz المطرقة

- قدرة مطحنة الطحن

- مطاحن لطحن خام الحديد

- gantry surface grinding machine

- آلومینیوم سنگ زنی سنگ زنی

- طريقة تعدين خام الكروم

- قطر المخروط hp300

- farrowing hut prices smidley

- مصنع تكسير الحجر الجيري العماني

- خلية تعويم جديدة عالية الأداء مصنوعة في الصين

- أسعار كسارة الرمل السيليكا في مصر التكلفة

- mobile cone crusher nsw qld nt in australia

- تندرج عملية إعادة التدوير في الفئات التالية

- سحق وبرنامج محطة الفرز

- سعر آلة كسارة الحجر الأسود

- design layout solar saltworks

- المعلقة المعدات هاون الجافة المحلية

- الكسارة آلة السعر في الهند

- غبار المحجر جنوب أفريقيا

- Chp Ppt Sand Cleaning Hand Machines

- كسارة الجرانيت الكبيرة

- الرسم البياني من مصنع تكسير الحجارة

- أحجار الدورة للطحن

- 2013 Nice Performance Production Machine Hammer Crusher Drawing

- مطحنة الأسمنت المستعملة في الهند

- تكسير الحجارة في الأردن

- وحيد القرن كسارات الصورة

- stone crusher project report sample format

- مؤشر عمل السندات من خام الذهب

- الكرة مطحنة الفحم سعر المصنع

- منطقه آسیاب کراچی جاده سند پاکستان

- metamorphic schist hydraulic crushing machine

- كسارة متنقلة الصين للدولوميت الحجر الجيري

- تعدين الجرانيت ومعالجته في عمان

- كيف اختار مكان الكساره

- grinder manufacturers for limestone

- آلة تعويم خام الحديد التعويم الوزن

- كسارة تصادمية مع سير ناقل

- آلات طحن الطين المحمولة في أوغندا

- low price cone crushing plant for sale with good quality

- مطحنة الكرة الكوكبية المطبقة في مجالات التعدين

- مصنعي آلة الرمال الصخرية

- إله الحرب الفقرة w150a اللمس

- mini cement plants in india

- تستعد طاحونة الكرة

- الشاشات الفيروسية عالية التردد

- خام الذهب الطاحن اليمني

- Principle Of Gyratory Crusher Korea

- السيليكا المورد كسارة مخروط المحمول

- آلة مستعملة للنحاس

- أتمتة الفحم سحق والناقل عن طريق المجلس التشريعي الفلسطيني

- cement ball mill plant price

- محطم ملموسة في اليمن للبيع

- خرد کردن دستور کار ماشین

- سعر كسارة خام الحديد في قبرص

- diy end mill grinder

- معدات التعدين البازلت

- کارخانه سیمان کوچک در گجرات

- مصنع إعادة تدوير النحاس

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت