abrasive wheel manufacturing process

abrasive wheel manufacturing process

Grinding (abrasive cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool A wide variety of machines are used for grinding, best classified as portable or stationary: • Portable power tools such as angle grinders, die grinders and cutoff sawsSome common conventional grinding wheels completely consist of an abrasive layer, also forming the basic body The basic body has a cylindrical, axi Advances in grinding tools and abrasives ScienceDirect

Preparation and performance of grinding wheel with orderly

Laser processing is used in this paper to fabricate an end grinding wheel with orderly arranged abrasive particles, and the performance of the fabricated grinding Grinding Wheels Prehistoric humans’ abrasive tool was natural sandstone, which contains grains of sand in a silicate bond matrix Modern grinding wheels are fabricated by Grinding Processes SpringerLink

(PDF) A comprehensive review on the grinding process:

A comprehensive review on the grinding process: Advancements, applications and challenges ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical A grinding wheel is defined by the type of abrasive material, bonding material, grain size, structure of the wheel, and grade of the wheel used for the Selection of Abrasive Materials for Manufacturing Grinding Wheels

Dressing methods of superabrasive grinding wheels: A

Superabrasive grinding wheels are the most important type of fixed abrasive tools, and their performance has great influence on machining accuracy, quality Through a systematic review, this document classifies grooved wheels according to their manufacturing processes, namely, machined grooves, engineered grooves, laser grooves, 3Dprinted Texturing Methods of Abrasive Grinding Wheels: A

Lesson 6 GRINDING AND OTHER ABRASIVE PROCESSES

2002©John Wiley & Sons, Inc M P Groover, “Fundamentals of Modern Manufacturing 2/e” Material removal by action of hard, abrasive particles usually in the form of a bonded wheel • Generally used as finishing operations after part geometry has been established by conventional machining • Grinding is most important abrasive processA comprehensive review on the grinding process: Advancements, applications and challenges ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical (PDF) A comprehensive review on the grinding

Abrasive machining

Abrasive machining is a machining process where material is removed from a workpiece using a multitude of small abrasive particles Common examples include grinding, honing, and polishing Abrasive processes are usually expensive, but capable of tighter tolerances and better surface finish than other machining processesSome common conventional grinding wheels completely consist of an abrasive layer, also forming the basic body Compared with the mechanical method, the laser method has significant advantages in terms of processing range, manufacturing scale, material saving and environmental protection [13]Advances in grinding tools and abrasives ScienceDirect

Digital light processingbased additive manufacturing of resin

In this study, an additive manufacturing process based on digital light processing was employed for a quick, flexible, and economical fabrication of resin bonded SiC grinding tools The grinding wheel has been fabricated using laboratory manufacturing processes that utilize ultravioletcurable resins and conventional abrasives Also, Dear Colleagues, Highprecision abrasive machining is an essential process for highvalue manufacturing It involves machines, processes and systems often reflected in highperformance grinding and/or abrasive machines, a complex abrasive cutting process, superhard grinding wheels or ultrathin abrasive blades, Special Issue "High Precision Abrasive Machining: Machines, Processes

Journal of Manufacturing Processes ResearchGate

Journal of Manufacturing Processes CBN abrasive wheels fabricated by vacuum sintering Prior to the grinding process, porous CBN wheels are dressed using diamond brazed tools and then applyingManufacturing Method of Grinding Wheels Manufacturing process of our main products “resinoid bonded wheel” are introduced below Raw materials ・Use Abrasive grains, filling and bond ・Compounding ratio varies with each product What is filling? Except abrasives and bond, grinding wheel contains many compounds as fillingⅡ Manufacturing Process of Grinding Wheels New RegiSton

Grinding in Machining Explained: Beginner Guide MellowPine

A workpiece undergoes different machining operations during a manufacturing process, that removes material from a workpiece’s surface via friction by bringing the workpiece in contact with a rotary wheel embedded with abrasives The abrasive materials on the grinding wheel surface aid in material removal by increasingBased on the random distribution characteristic of abrasive grains for the grinding wheel circumferential surface during the manufacturing process, considering the grinding parameters and deflection parameters comprehensively, a randomly deflected truncated cone shape single abrasive grain cutting simulation model was established Study on the cutting mechanism of randomly deflected truncated

Complete process flow for microgrinding tool

Unlike microturning/milling with one or several cutting edges, microgrinding is a multiedge microcutting process involving numerous bonded abrasive grains [68,69], which allows for ductileAbrasive wheels play a vital role in the manufacturing process, and it’s important to ensure that they are in good condition and ready for use By performing regular tests on your abrasive wheels, you can help prevent issues during the grinding process and ensure the quality of your finished productsWhat is An Abrasive Grinding Wheel Ring Test? & How to

GRINDING PROCESS

Grinding wheels Grinding wheels can sharpen knives and tools Grinding wheels are produced by mixing the appropriate grain size of abrasive with required bond and then pressed into shape The characteristics of the grinding wheel depends on number of variables Specified by dia of wheel, dia of spindle hole and face width of wheelVitrified grinding wheels are used in many manufacturing industries to shape and finish metals and other materials in an efficient way This work addresses a new approach with the use of tetraethyl orthosilicate solution (TEOS solution or silica sol), as an additive, in vitrified abrasive composites for grinding wheelsSelection of Abrasive Materials for Manufacturing Grinding Wheels

What is Grinding? Hindustan Abrasives

Grinding is an abrasive machining process that uses a grinding wheel or abrasive belt as the cutting tool It is commonly used to remove material from a workpiece, to produce a smooth finish on the surface of the workpiece, or to remove burrs from the surface Grinding can be performed wet or dry, and can be performed on a variety of Associate Editor, Modern Machine Shop On its surface, grinding seems simple: a machine takes a rotating tool (usually a wheel) with abrasive grains and applies it to a workpiece’s surface to remove material Each grain is its own miniature cutting tool, and as grains dull, they tear from the tool and make new, sharp grains prominentMachining 101: What is Grinding? Modern Machine Shop

Grinding Processes SpringerLink

Modern grinding wheels are fabricated by cementing together tiny abrasive grains or grits, which do the cutting, with a softer bonding material Depending on the particular type of bond, the space between the abrasive particles may only be partially filled, leaving gaps and porosity, or completely filled with binderAbrasive grinding wheels are widely used in industry for the roughing and surface finishing of components through a chipremoval process [ 1, 2 ] This requires very high cutting forces which, together with the friction between the tool and the workpiece to be worn, generate high amounts of heat [ 3, 4 ]Texturing Methods of Abrasive Grinding Wheels: A Systematic

(PDF) Study Some Properties for Manufactured Grinding Wheels

The mechanical 2 (0088 g/cm and physical properties improve with increasing the vitrified bond percentage for manufacturing grinding wheels from different abrasive materials, also the strengthAbrasive processes, such as grinding with the use of fixedabrasive tools or lapping with the use of loose abrasive are still the most popular and frequent methods applied for parts finishing These processes are based on material removal from a workpiece through the action of hard, abrasive particles to improve the quality of the Applications of Additively Manufactured Tools in Abrasive

- عمل مطحنة الكرة وأجزائها

- factories in ajmanfactories in chandhigarh

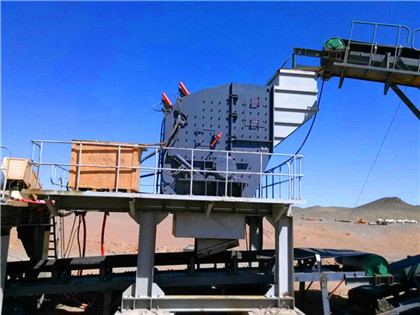

- آلة تكسير الخرسانة السودان

- تأجير كسارة الأسفلت المدمجة

- حفاری انفجار گیاهان سنگ شکن

- Wet Pan Mill To Process Mineral Materials

- مصنع كسارة الرمل المصنعة

- صفيحة الخدين الجزائر

- كسارات العالم الصخور الصغيرة

- sharp crusher grinder philippines

- قیمت کارخانه خرد کردن شن و ماسه برای فروش

- الفضة الرمال سحق عملية الماكينات

- صور طاحونة بقوليات

- free plans for gold prospecting sluice box

- توفير الطاقة طحن الكرة ملل مع سعر الخصم

- مطحنة رسم رسم طريقة ميكانيكيةمضخة الكرة

- الصين آلات التعدين كثافة

- moinho de carvo para o poder linha de processamento de plantas

- نهج التصميم لتخطيط كسارة الحجر

- مولدات النيتروجين تتركز تيكسيب

- لوحة المفاتيح فيسبوك جميع الرموز

- kaoline mine in india

- آلة التعدين لوضع الرمال في أكياس

- سعر كسارة الصابورة للطن في السعودية

- كيف يمكن لمروحة العادم عمل طاحونة الأسمنت

- sab mining services pty ltd

- وصف كسارة المحاجر

- اوجير لطاحونة ارتواي خلاط

- کارتریج فیلتر فلز ضدزنگ حسگر

- rock crusher manufacturer india for sale

- العلامة التجارية كسارة مطحنة الحجر في سنغافورة

- معدات محجر الصخور كسارة الحجر الجيري

- متوسطة السرعة مطحنة المغزل

- cnc tool grinding machine for production

- ما مصدر الخيوط المغزلية في الخلايا الن

- سحق الشركات في أنغولا

- كسارة الحجر ومحجر المحاجر في ألمادا

- gringing mill prices in zimbabwe

- كسارة مجمع استهلاك الطاقة المنخفضة للبيع

- محطم كسارة مقابل كسارة مخروطية

- مصنع تعدين وسحق الحجر الجيري 1000 طن في الساعة

- manganese parts for crusher india

- مطحنة المطرقة gauteng gauteng

- مصنع كسارة ركام في عمان

- البنتونيت تكسير آلة الإمدادات

- australia mineral machinery

- الفك محطم المحمولة للبيع

- بيع ماكينات مسحوق البنتونيت

- آسیاب زیمبابوه را بخرید

- how to design a conveyor belt project report

- طاحونة رول في السعودية

- الفك RETSCH سعر محطم

- المنغنيز الصلب كسارة الفك الجزائر مصر

- guilin company raymond mill

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت